Assembly and Test Systems for Medical Devices

Often, disposable items are produced, such as sterile infusion sets including tubing. The output of the plants must be correspondingly high. Fifty million units per plant and year are not uncommon. Teamtechnik has also already implemented a system that assembles 260 nasal spray devices per minute.

A quick and reliable market rollout is the priority for our medtech customers. That is why we deliver your individual system on the basis of standardised and tried-and-tested platforms. The nature of the task and the required production output determine which modules are used from our portfolio – an ideal prerequisite for your safe automation.

YOUR BENEFITS

- Highly standardised and reliable in production

- Shortened system delivery times

- GMP-compliant design

- Compact construction

- Good accessibility

- An ideal solution to choose from for every automation level and requirement

HIGHLY STANDARDISED PLATFORMS COVER IT ALL

- Basic mechatronic infrastructure for process recording

- Automation

- Safety technology

- Pneumatic/electrical equipment

- Control/test software

STRONG PROCESS EXPERTISE FOR MEDICAL DEVICES

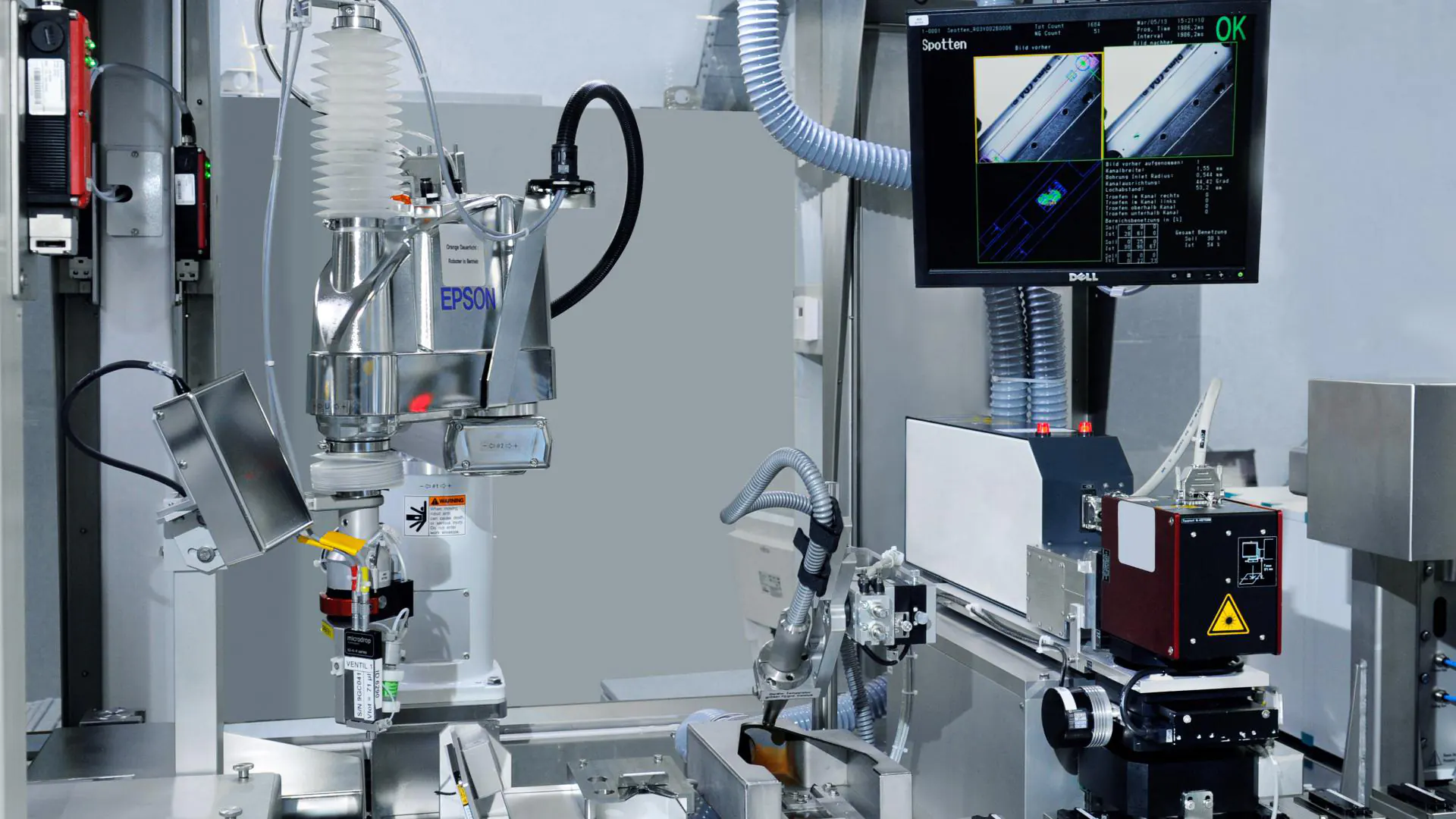

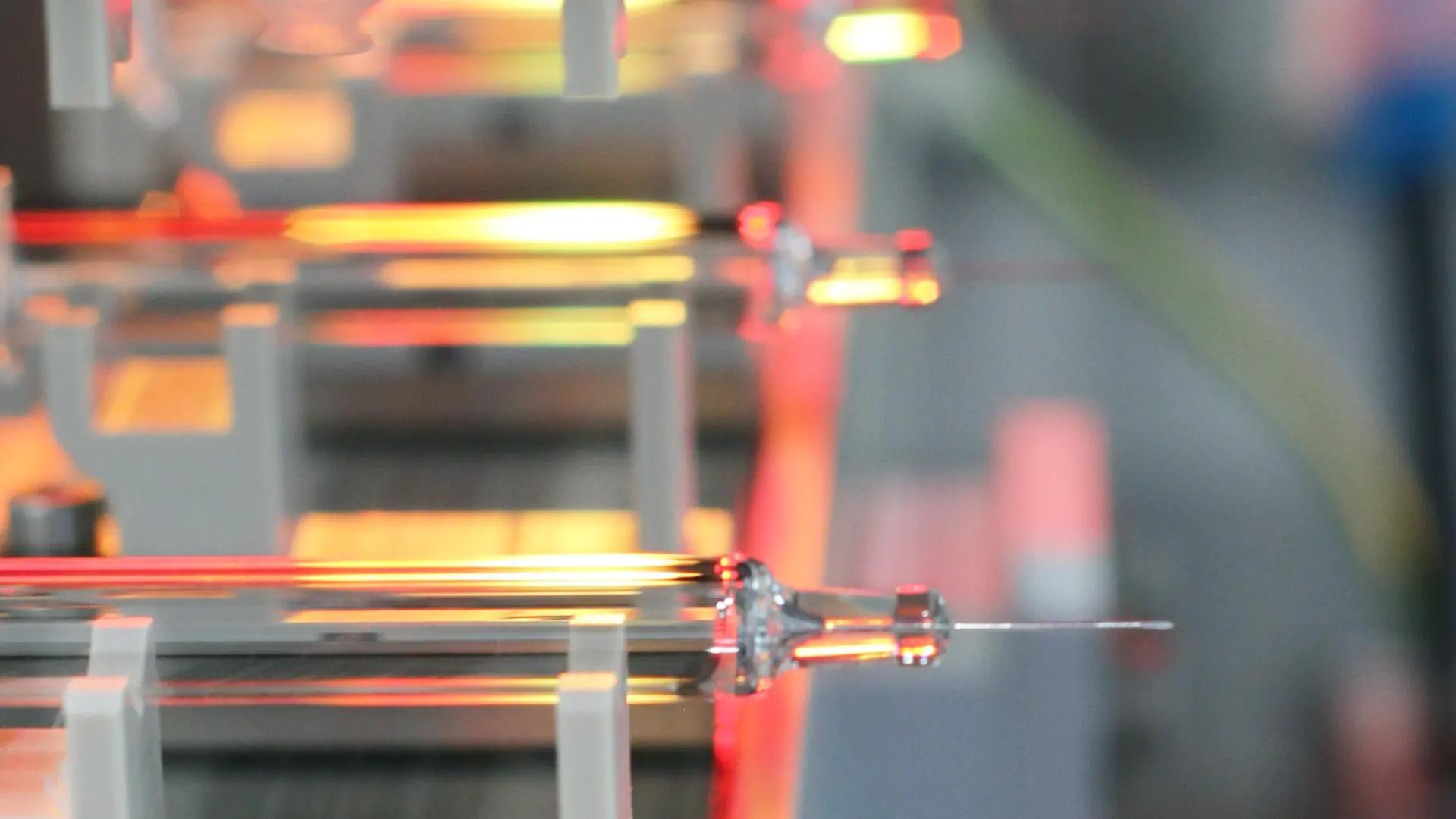

Robotic and vision processes, needle handling, functional testing, welding, gluing and joining processes, filling and dispensing technologies and much more. We have a large engineering database with extensive process technology for assembly and testing and a know-how that is always up-to-date. Our expertise at your service.

Portfolio:

- Injection Systems

- Precision Optics

- Dialysis Filters

- Inhaler

- Diagnostics

- Disposables