Precision Optics

8 BILLION CONTACT LENSES EVERY YEAR ON THE Teamtechnik LINES

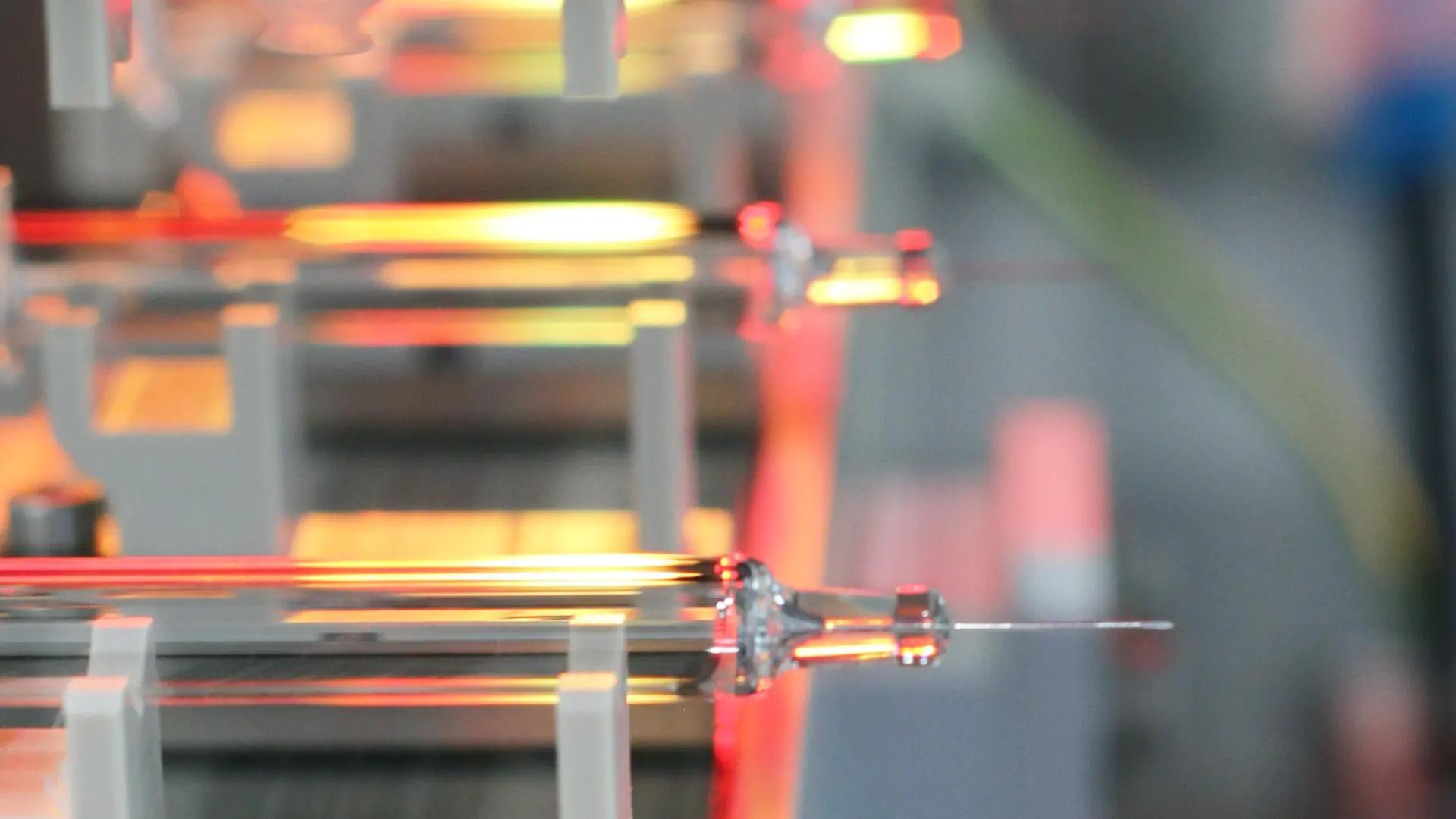

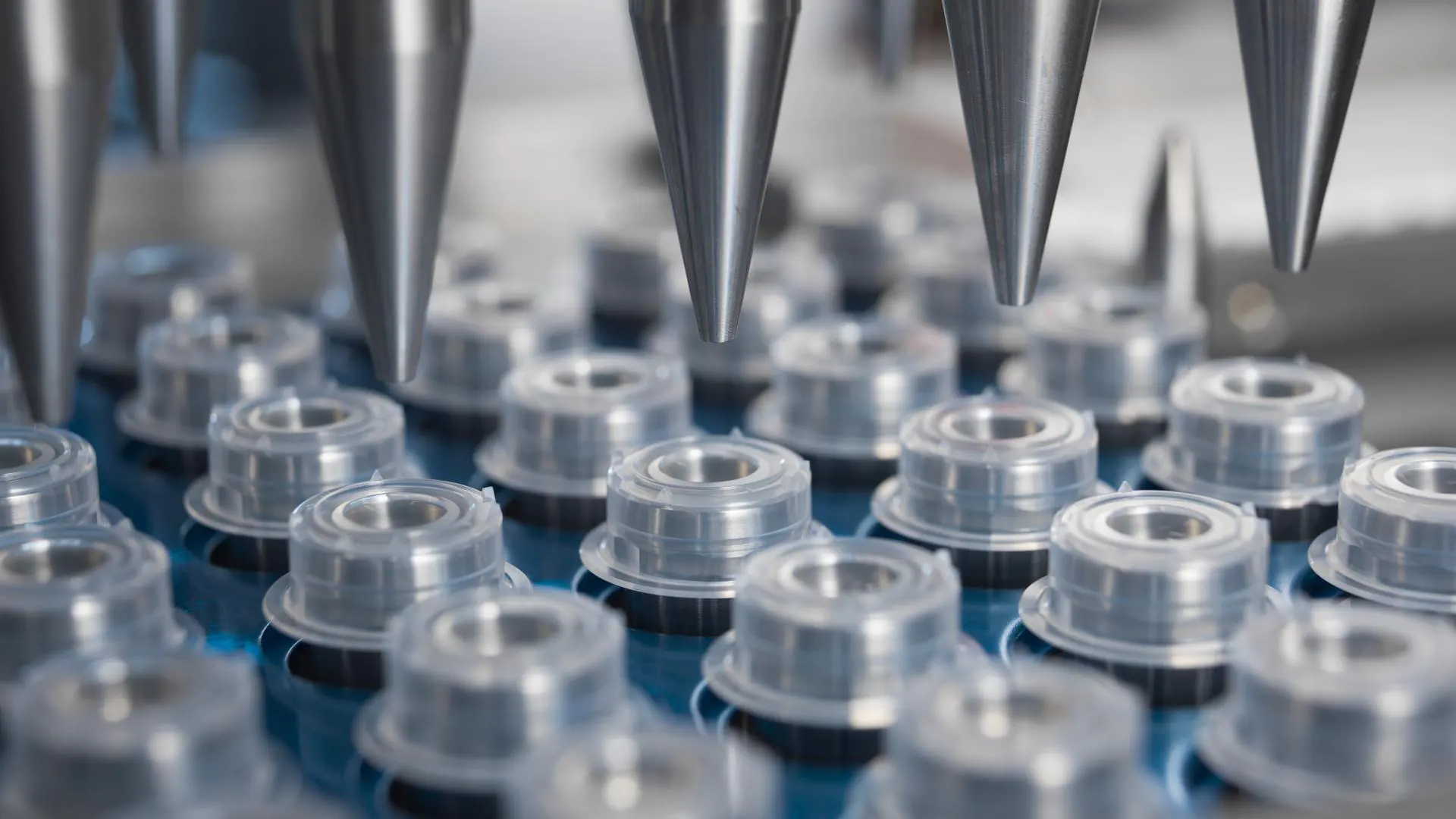

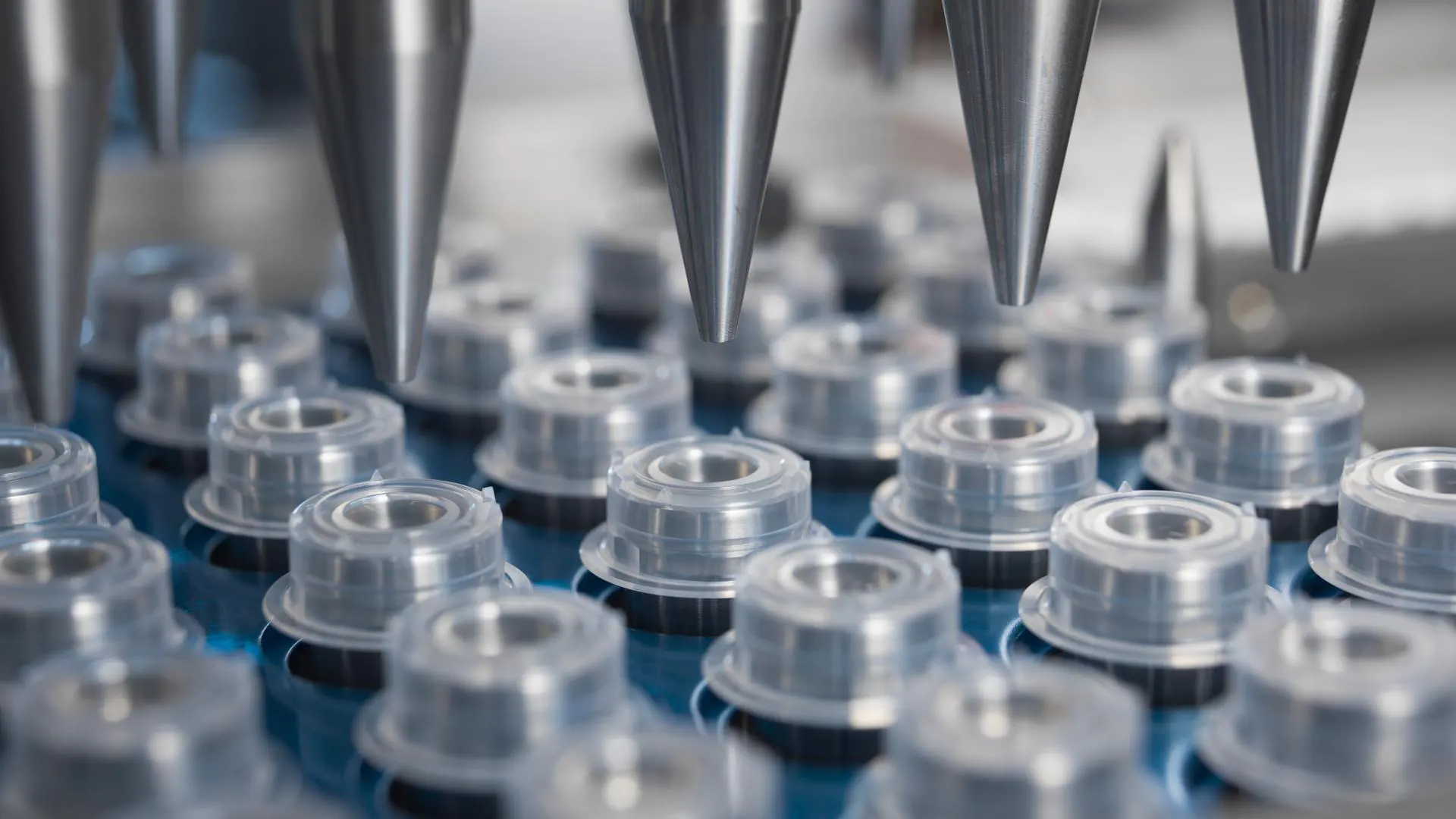

Daily contact lenses are also produced on Teamtechnik systems. Teamtechnik has supplied several dozen systems to the largest customer in this sector, having a total capacity of several billion daily disposable lenses per year.

Implemented processes

- De-moulding from injection moulding machines

- Nitrogenation

- Colour printing processes

- Monomer dosing

- Curing

- Cracking/Decapping

- Visual inspection

- Hydration

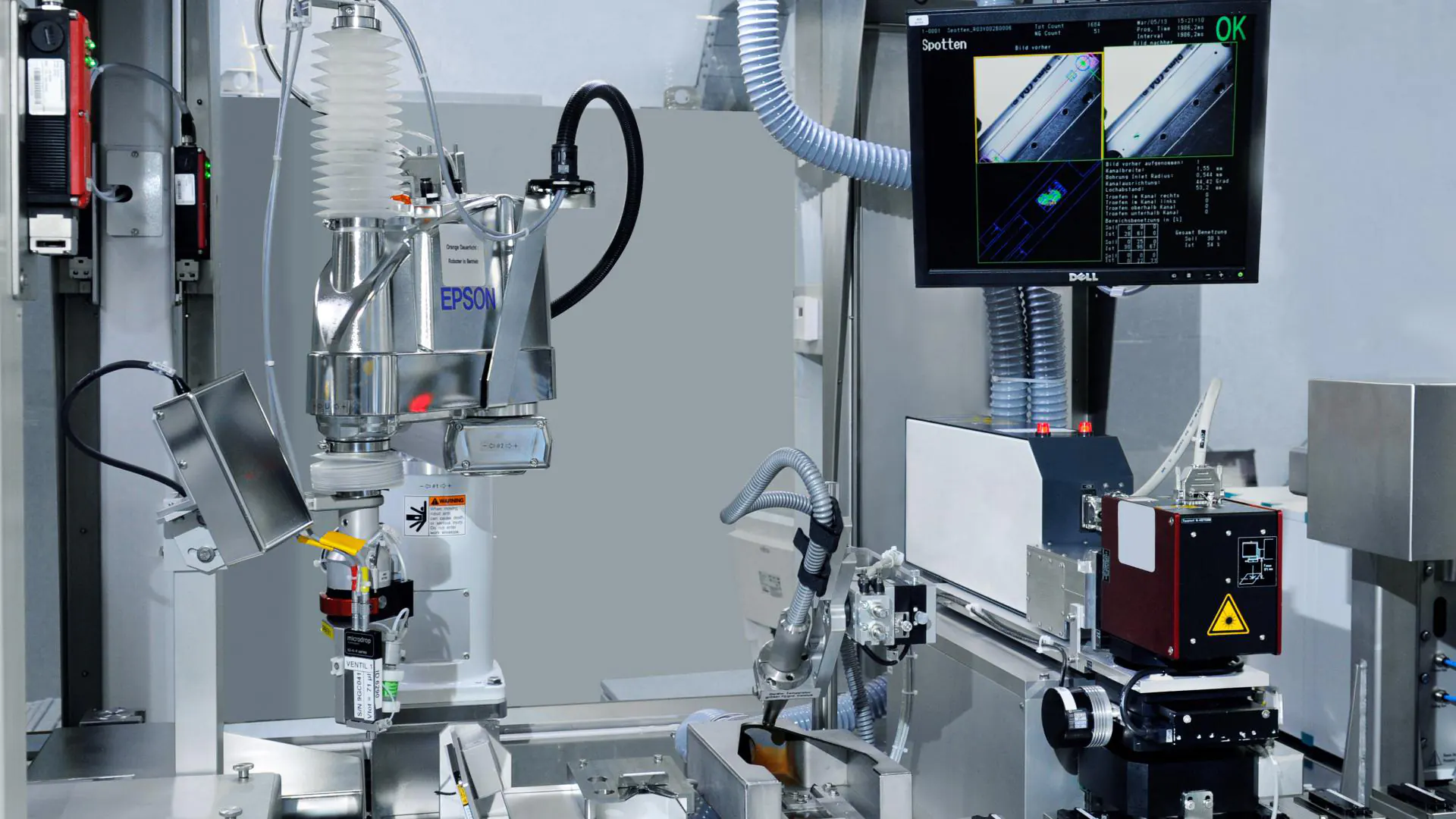

Ultrasonic cleaning machines for precision optics

Increasing cleanliness requirements and consistent cleaning results are common demands for precision optics. UCM, a member of the Ecoclean Group, stands for Ultrasonic Cleaning Machines and offers optimized solutions ranging from in-process to final cleaning prior to coating. With the broad spectrum from aqueous, multi-stage ultrasonic cleaning processes to ultrapure water rinsing with subsequent drying processes, UCM always offers the optimum solution for fine cleaning processes in the entire production chain.

UCM is a full solution provider for industrial cleaning applications, ranging from pre-cleaning via intermediate cleaning to fine and ultra-fine cleaning requirements, including cleanroom applications.

UCM is a manufacturer of multi-stage immersion-type ultrasonic cleaning lines. All equipment meets the highest standards of substrate cleanliness. Our sophisticated modular design allows these systems to be individually and cost-efficiently adapted to any application and requirement. This includes sputtering, ultrasonic resonators for different frequencies and power levels as well as re-circulation and filtration systems. Various processes, including passivation, DI rinsing, lift-out, and drying (blowing off, warm air, vacuum, IR) are applied to meet the specific task.