Cleaning Technology in the Automotive and supplier industry

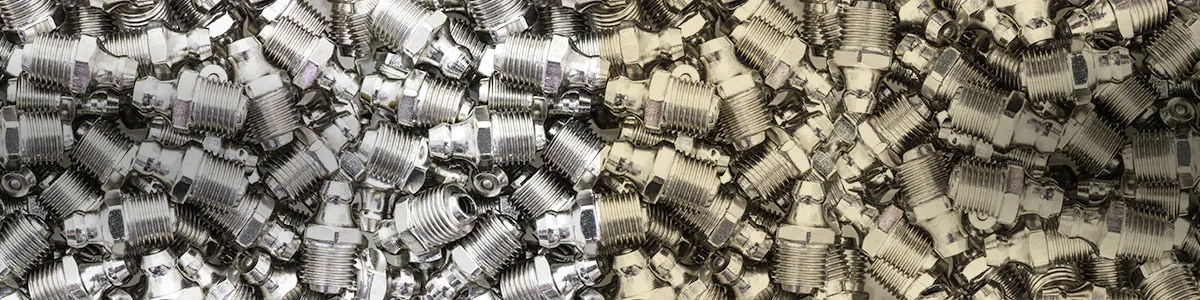

Whether it is cars, vans or trucks - in no other industry are the requirements for cleaning parts as high and varied as in the automotive industry. From engines and gearboxes to parts for injection, brake, steering and driver assistance systems and chassis components, parts cleanliness plays a decisive role in the quality of downstream processes and in the long-term flawless and safe function of the components. To ensure this reliably, Ecoclean Company offers optimally matched and energy-efficient cleaning solutions which enable companies to meet the respective specifications for particulate and thin-film cleanliness in a requirement-oriented, consistent and economical manner.

Cleaning technologies for automotive components

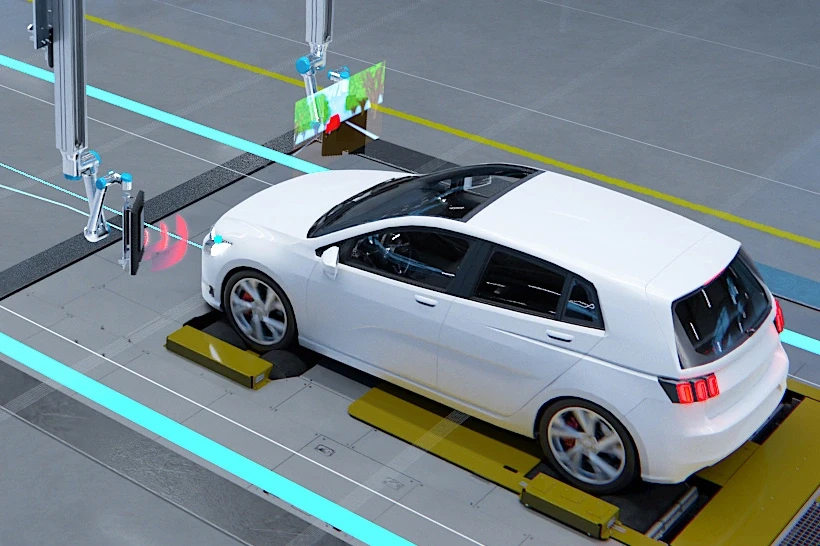

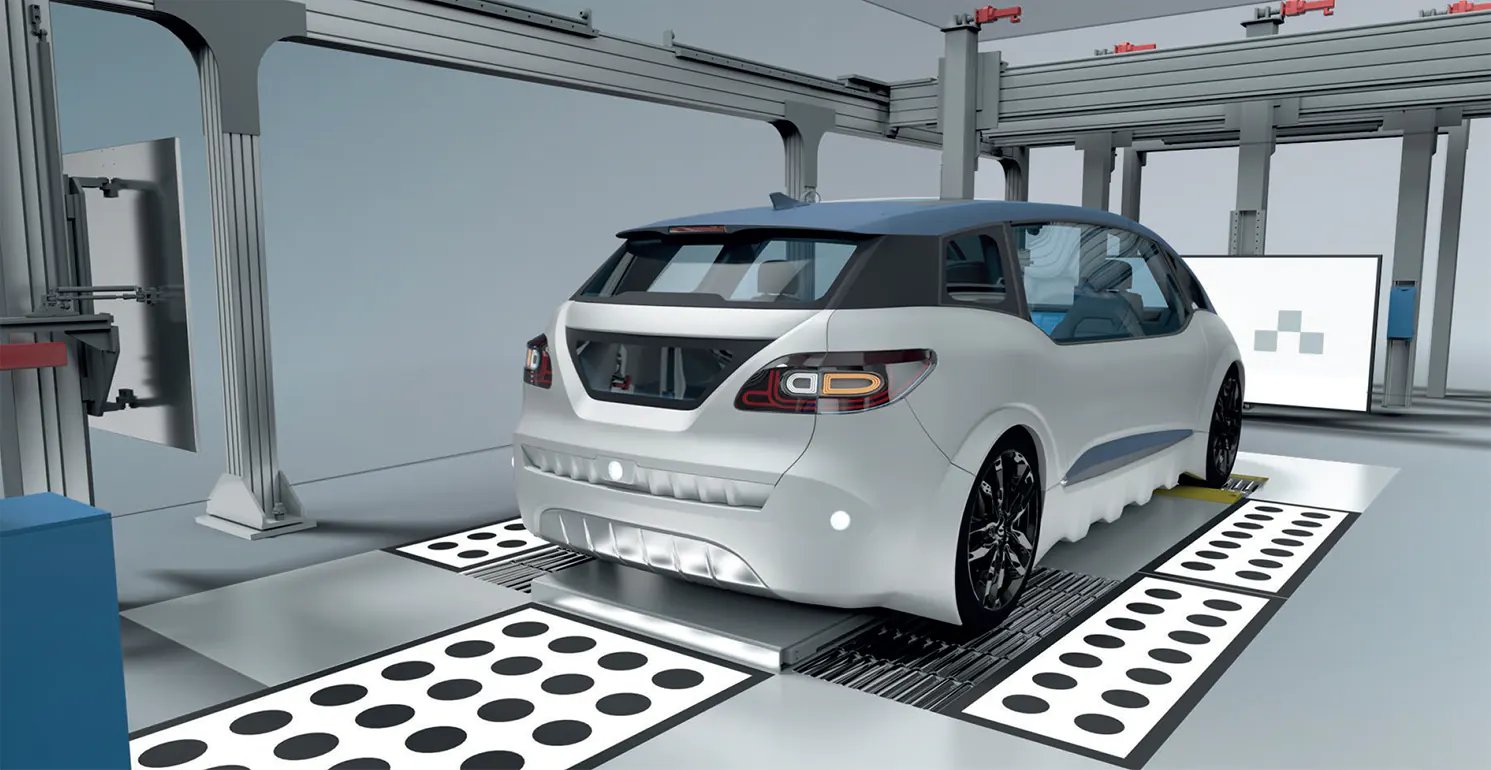

Ecoclean company is a full-range supplier of future-oriented, globally available solutions for industrial parts cleaning, aqueous surface treatment and customized automation. Aqueous cleaning and deburring systems adapted to the specific requirements and applications of vehicle manufacturers and suppliers (e.g. cleanliness specifications, throughput, cycle times) are used, for example, to clean and deburr drive and transmission components such as crankcases, cylinder heads, crankshafts, camshafts, gearboxes and housings as well as hydraulic parts. For efficient batch cleaning, such as parts for brake, steering and injection systems, Ecoclean offers water-based and environmentally compatible solvent-based cleaning machines, which also meet the highest cleanliness requirements in an economical manner. With our surface treatment solutions, parts such as cylinder liners and brake discs can be activated prior to coating to prevent corrosion and reduce fine dust emissions just as effectively and efficiently as weld seams on chassis parts can be cleaned. For partial cleaning applications and tasks in assembly, different dry process technologies are available.

Comprehensive expertise in parts cleaning for the automotive industry

To solve the highly varied tasks in the automotive and supplier industry in a requirement-oriented, sustainable and efficient way, comprehensive technological expertise is indispensable. However, application know-how is also called for. Thanks to our many years of experience and numerous successfully completed projects for OEMs and suppliers around the globe, we have both. In our extensively equipped Technology Centres including cleanliness labs and clean rooms for quick checks on technical cleanliness, we can carry out cleaning tests with originally soiled parts under near-production conditions. Based on the respective material, component geometry, type of contamination, cleanliness and throughput requirements, we develop and automate flexible cleaning solutions that are both technically and economically optimized.

Components:

- Cylinder head

- Crankshaft

- Camshaft

- Cylinder block

- Con-rods

- Turbochargers

- Gear units, e.g. transmission valve bodies

- Gears

- Gearbox housings

- Injection systems, e.g. valves, nozzle needles

- Steering systems

- Brake systems, e.g. brake discs, hydraulic parts

- ABS parts

- Chassis components

- Mass-produced parts

Applications:

- Intermediate cleaning during production processes, e.g. after machining

- Final cleaning before assembly

- Surface activation, e.g. roughening prior to coating

- Deburring and cleaning before assembly

- Cleaning with corrosion protection or passivation

- Ultrafine cleaning to cleanliness specifications