Consulting & Planning: From initial idea to SOP

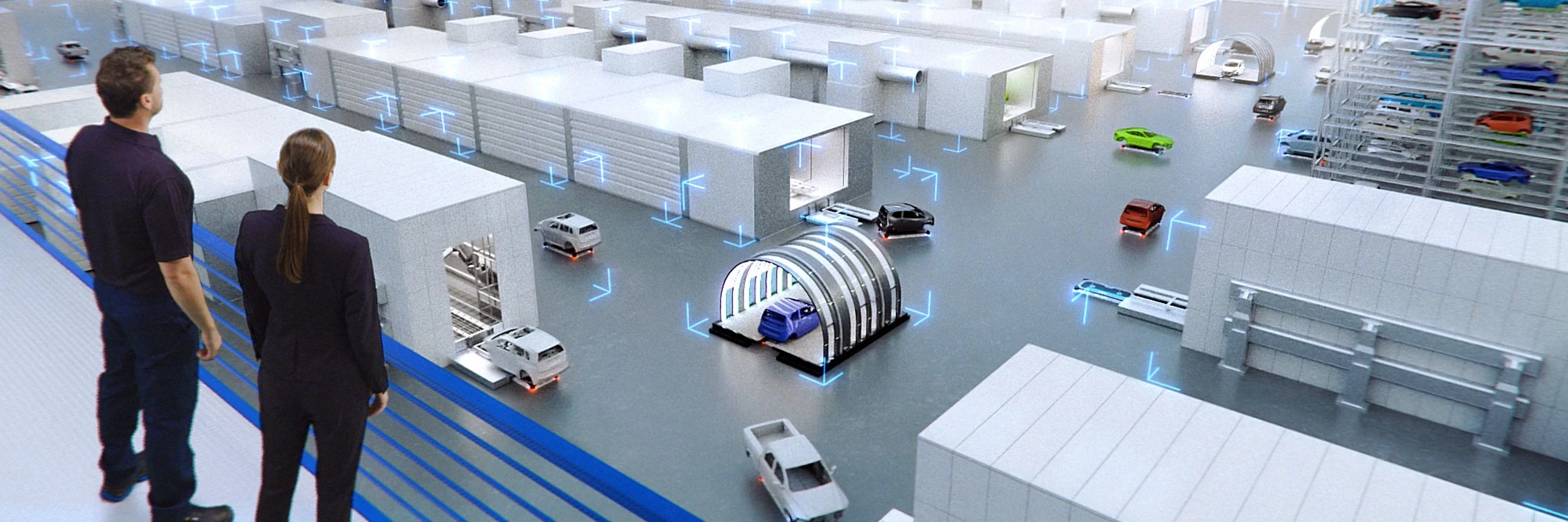

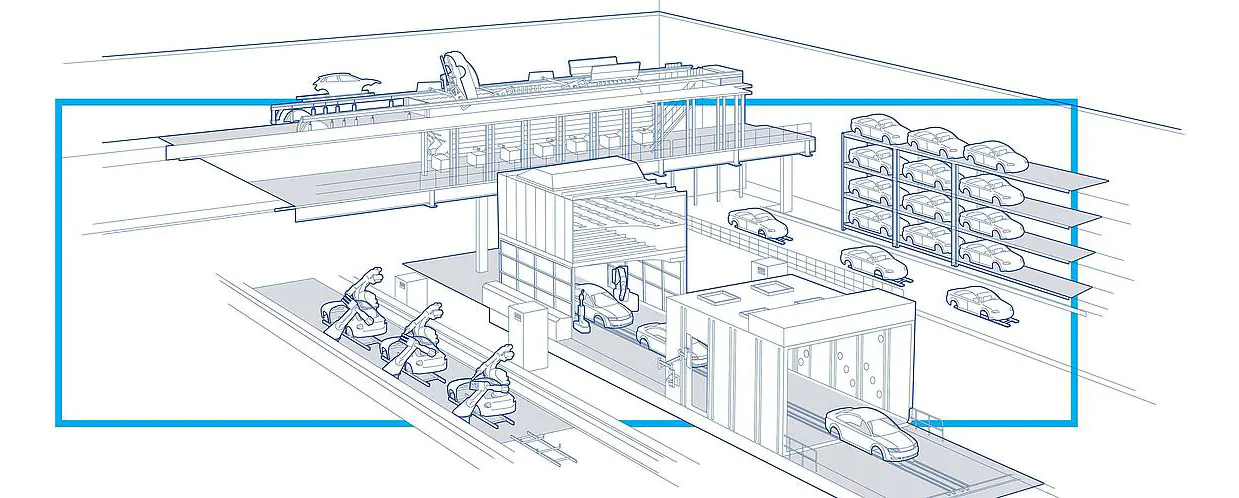

Applying our experience alongside virtual planning methods such as CAD planning, material flow simulation, we can provide customer-specific layouts to meet the most diverse requirements in terms of efficiency, interface optimization, sustainability and productivity.

This prevents errors from the planning stage onward, and sets you on the right course to sail through implementation without a hitch.

Many years of planning experience, state-of-the-art technology and extensive automotive industry knowledge ensure that we implement your individual requirements cost-effectively.

We take an integrated approach to plant planning; we analyze the structure, logistics and equipment of your process sequence, and we do it fast. Our expertise helps you optimize your processes, reduce overall planning costs and increase productivity.

Our consulting and planning process is designed to define your current situation, identify how your operation links together and leverage those interfaces. By harmonizing workflows, we’re often able make significant improvements in manufacturing processes and throughput times. We find that smart tools and utilities and lean layouts are key prerequisites in reducing unit costs effectively.

We take a result-oriented and systematic approach to project management. So, when planning logistics and process sequences and implementing the resulting measures and targets, we ensure everything happens on time and nothing compromises your operations.

During the ramp up, the track & tracing shop floor management monitors the implementation so that you can quickly and flexibly leave obstacles behind. After a successful SOP we are handing over the controls back to our customers, because our primary goal has been achieved: The customers production is up and running, Although, the production optimization continues. Availability, performance and quality will be optimized continuously always including digital solutions as the main drivers for future production efficiency.