ADAS Test Systems

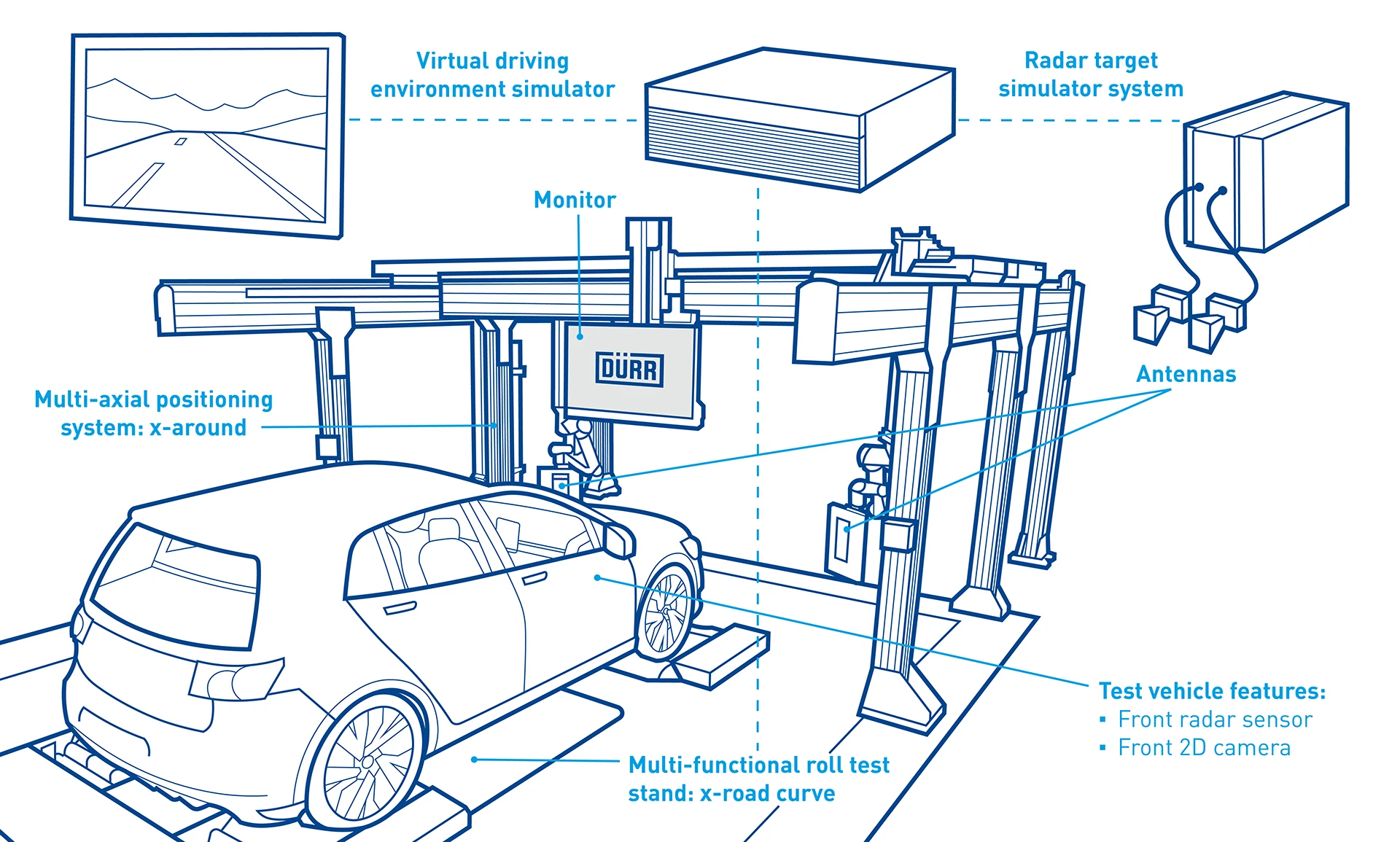

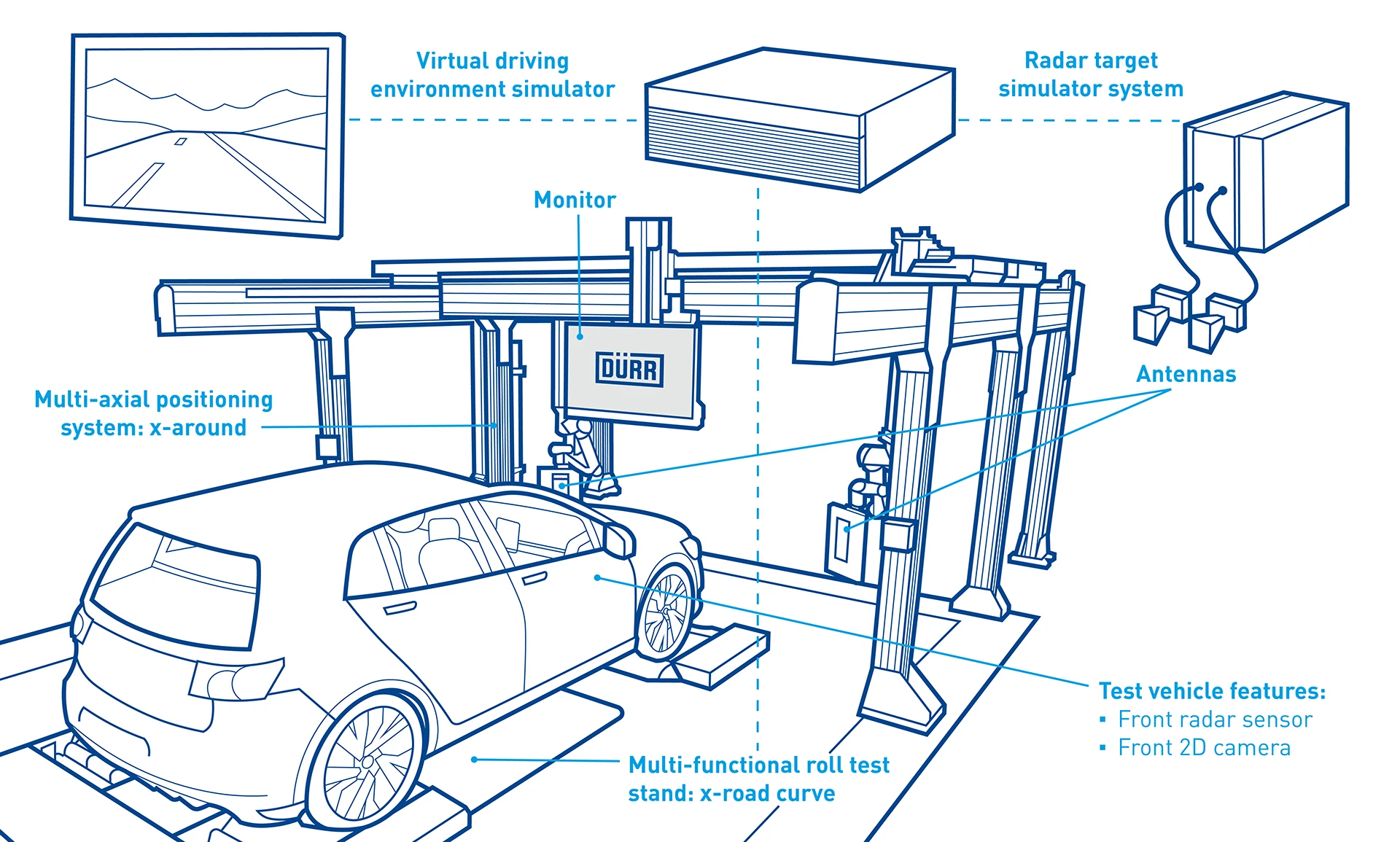

x-proof 360

The essential system to prove modern vehicle safety

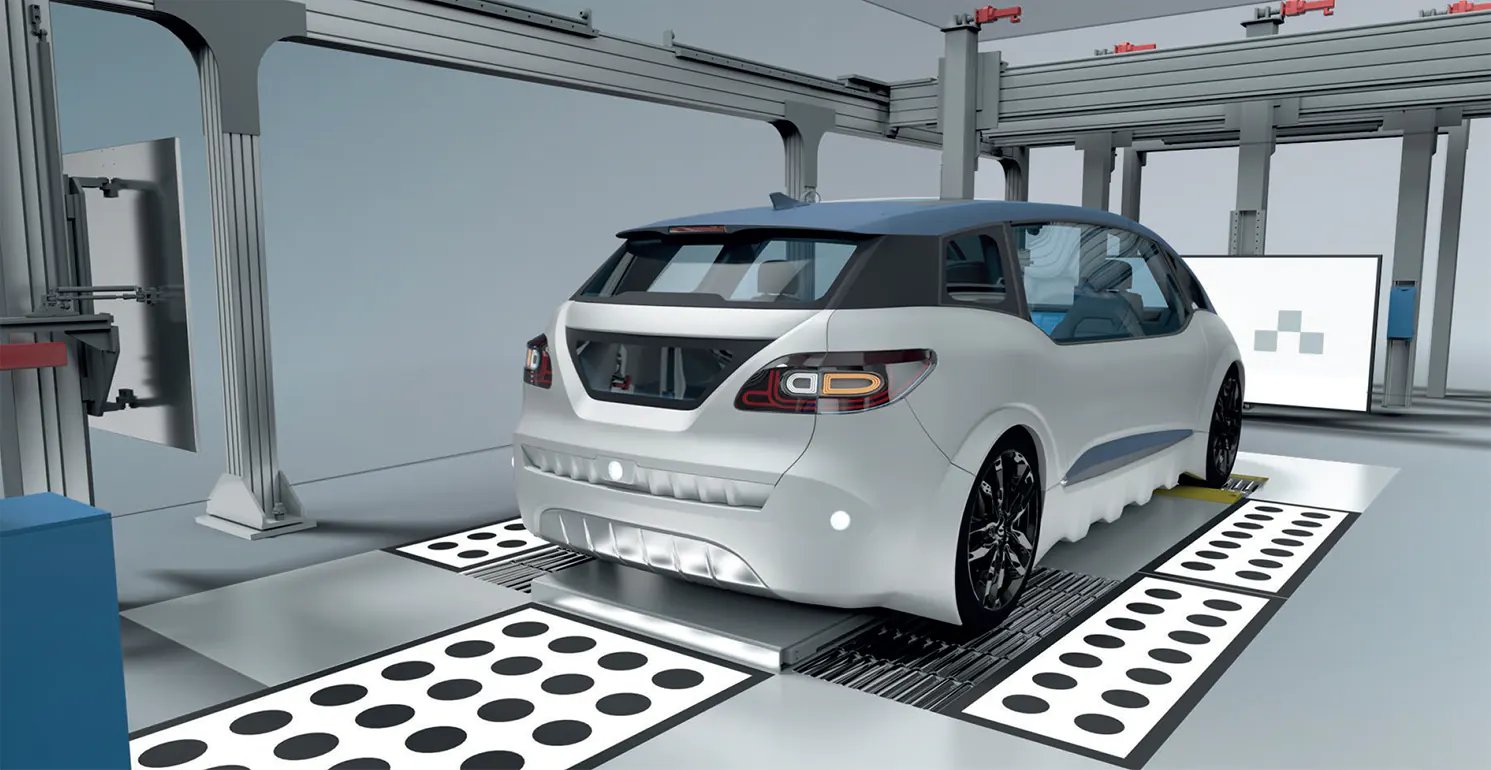

Automated driving will soon be a mandatory part of every new vehicle, and autonomous driving is no longer a distant vision of the future. In order to ensure the safety of automatic driving functions today as well as autonomous driving tomorrow, Dürr has created the x-proof 360 essential setup for Vehicle-in-the-Loop tests of ADAS/AD functions by combining over-the-air stimulation and two of our cutting-edge products:

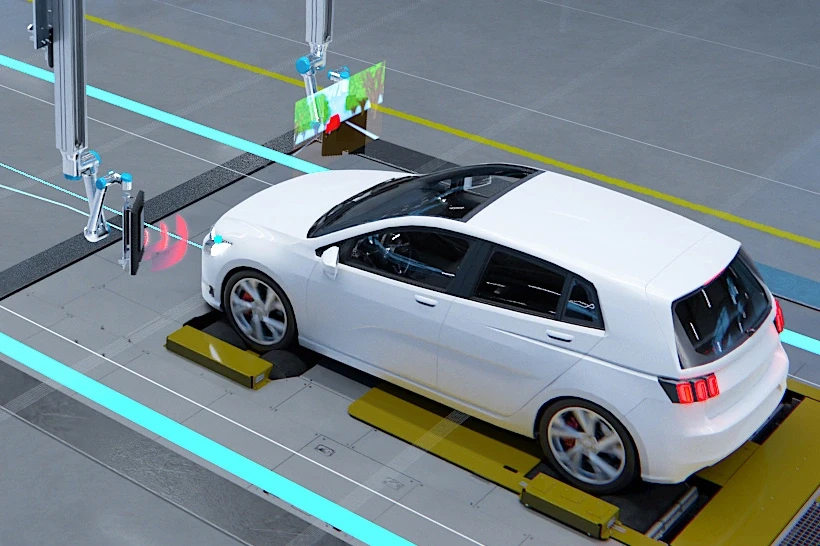

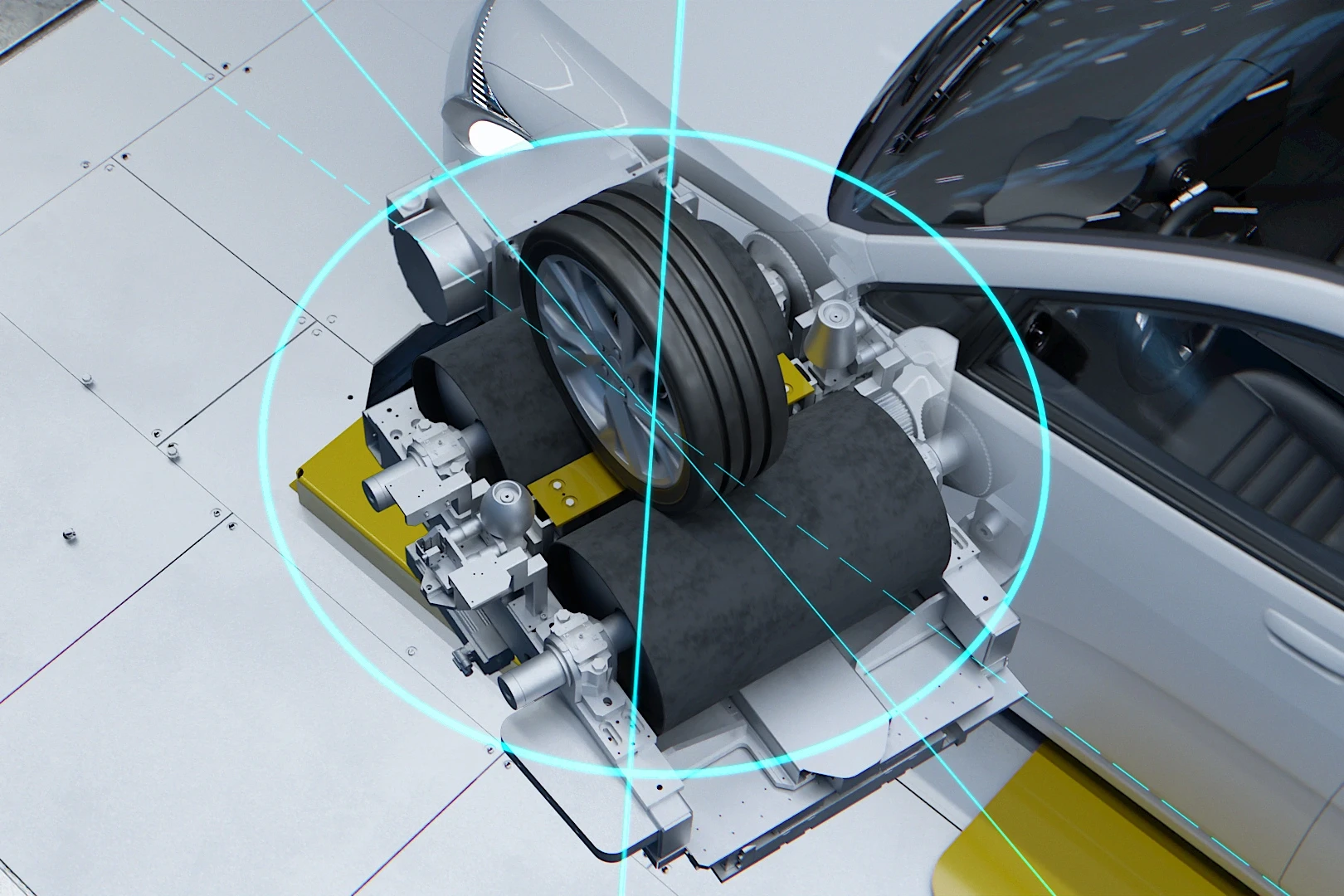

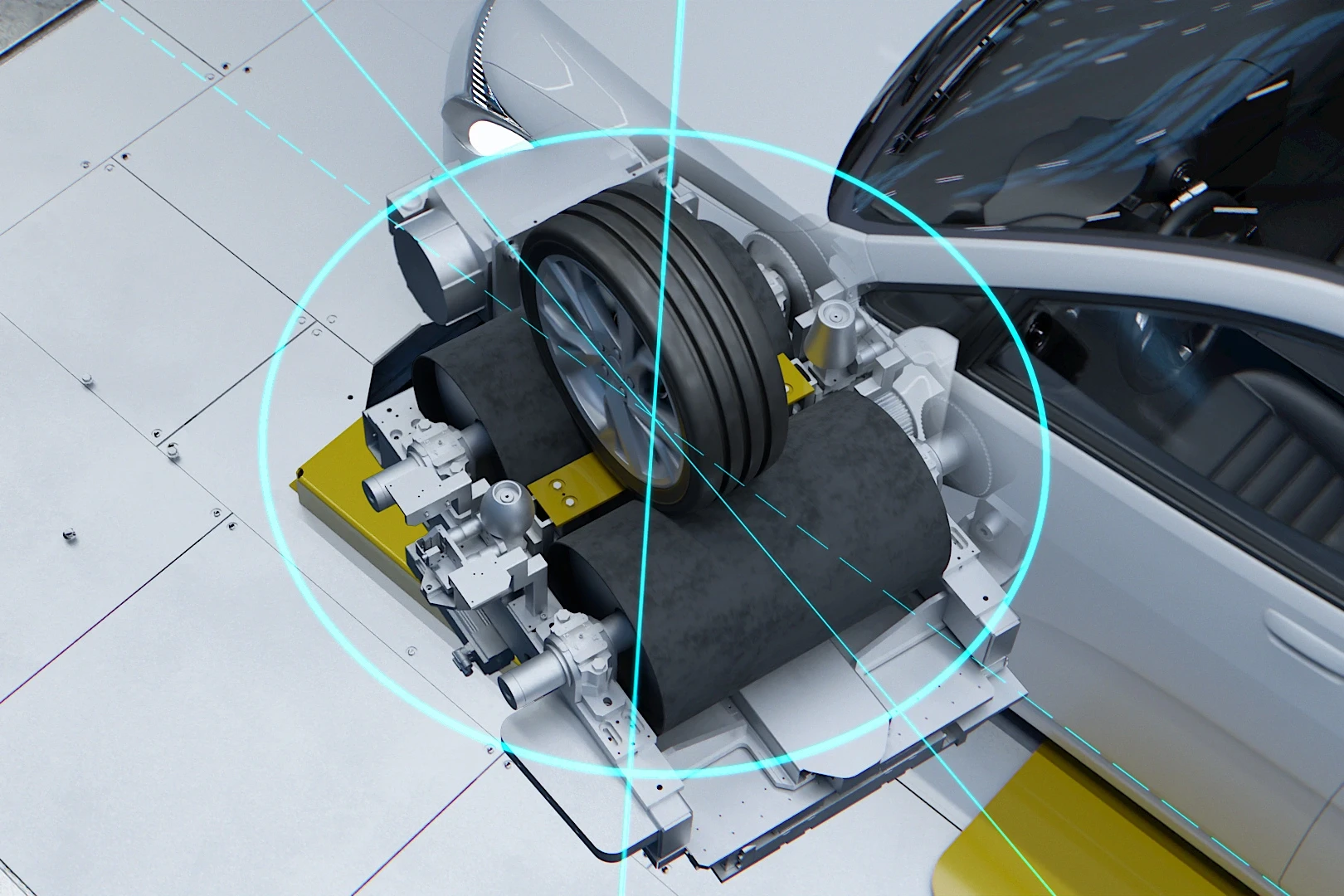

x-road curve

The multi-function roll test stand with steering capability offers all conventional features of a roll test stand and allows the vehicle to not only drive forward, but to perform cornering maneuvers as well.

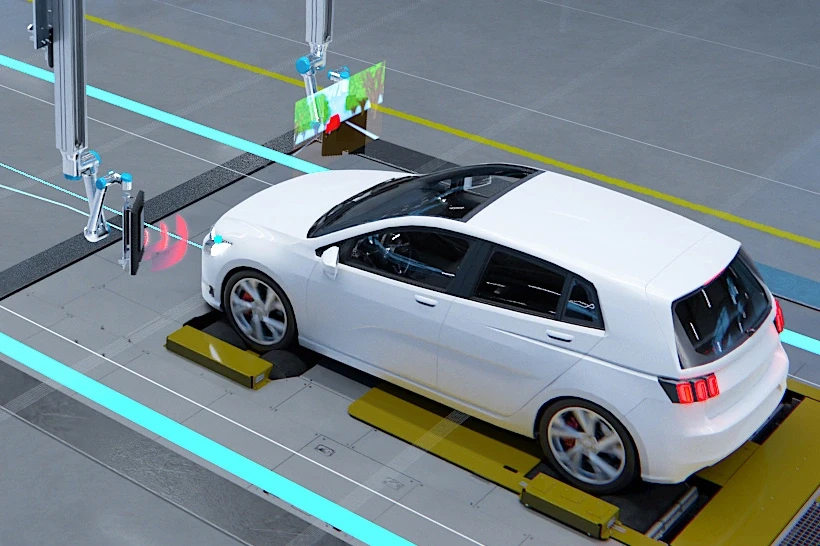

x-around

The multi-axial positioning system for dynamic scenarios offers full flexibility and precise positioning for over-the-air stimulation equipment, even in case of dynamically movable objects in front of the vehicle.

By synchronizing the real test vehicle behavior and simulated object movements with a virtual driving environment using over-the-air stimulation, the x-proof 360 enables tests of various ADAS and autonomous driving tasks.

Supported ADAS systems

Dürr’s x-proof 360 Vehicle-in-the-Loop setup using over-the-air stimulation covers all relevant safety-critical automatic driving functions such as:

- Advanced Emergency Braking Systems (AEBS)

- Forward Collision Warning Systems (FCWS)

- Automatic Cruise Control (ACC)

- Automated Lane Keeping Systems (ALKS)

- Lane Departure Warning (LDW)

- Active Lane Change Assistance (ALCA)

- Blind Spot Monitoring (BSM)

- Safe Exit Assistance (SEA)

- Intelligent Speed Assistance (ISA)

- Traffic Sign Recognition (TSR)

- Adaptive High-Beam Systems (AHBS)

- Adaptive Forward Lighting (AFL)

- Steering Assistance Systems and Active Steering Systems (also steer-by-wire)

The benefits

The benefits for applications in the fields of R&D, homologation, end-of-line and periodic technical inspection are manifold:

- Using a real vehicle in a laboratory environment

- No fixation and no modification required on the vehicle

- Sensor stimulation over the air with variable targets

- No large, fenced proving grounds necessary

- No dependencies on environmental conditions (e.g., weather, temperature, track, operators)

- Highly reproducible and repeatable test results

- Easy iteration and variation of manifold test scenarios

- Reduced staff requirements and test setup effort

- Safe operation conditions especially in case of critical maneuvers for operators and for the vehicle under test

- Ready for testing of autonomous driving functions up to level 5