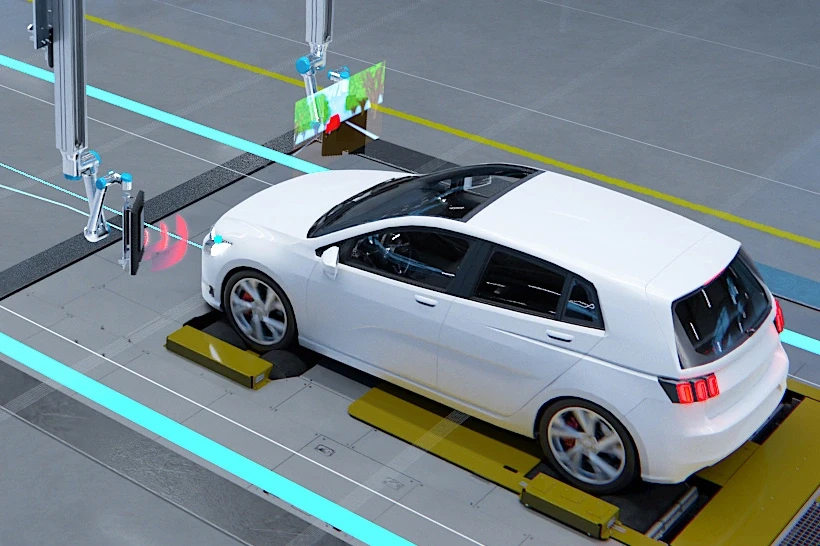

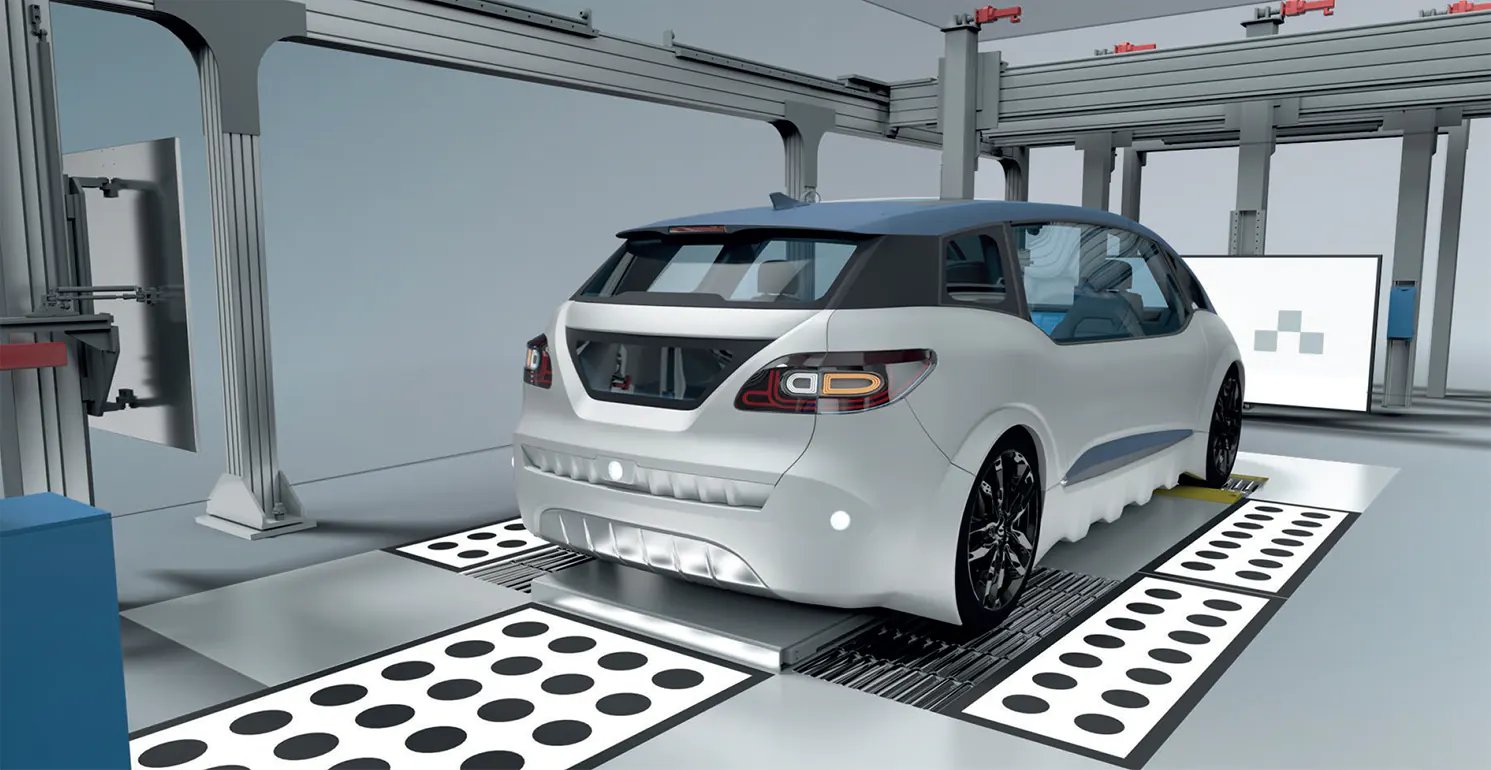

Conveyor

The success of our conveyor systems comes down to continuous enhancement, maximum reliability and low maintenance. Whether in a new installation or in retrofits, our conveyor systems are standardized to meet current quality benchmarks.

We supply a variety of overhead and floor conveyors, together with automated guided vehicles (AGVs), which meet a variety of different requirements, depending on the ergonomic and cost factors involved. The products in the portfolio are used for the pre-assembly of components and for unit assembly (marriage).

Overhead conveyors

Electric monorail systems are available as standardized systems and as a special solution:

- Lightweight EMS for the transport of smaller components up to 500 kg, such as doors, cockpits, engines and other assemblies

- Heavy-duty EMS with a payload capacity of up to 3,000 kg for transporting bodies. We have produced special designs up to 7 tons

We supply and develop hangers with stroke scissors with a stroke of up to 4.5 m in a variety of different designs, each individually adapted to customer needs. This allows you to set up optimum ergonomic conditions for every work cycle and the transfer of logistics and transport routes inside the factory.

Vertical Adjustable Carrier (VAC)

Height-adjustable load-bearing devices (VAC) can be used in combination with electric monorail systems or the Twin Trolley System (T.T.S.®). The scissor lift ensures hanger stability and allows individual height adjustment at every work zone. Body carriers are available as C-, T- or four-arm hangers. For lifting, there is a polyurethane belt with integrated steel cables designed for a payload of up to 3 tons.

You have the option to replace conventional busbars with non-contact energy and data transmission. This results in less wear, higher availability and, ultimately, minimized repair and maintenance costs. A swivel arm system enables the transfer from overhead to floor conveyors. The system can also be equipped with a body locking device.

Thanks to its minimum height requirements, VAC conveyor can be used in almost all existing plants in the body shop, painting and final assembly areas. This provides complete accessibility to the body and can be used in flow or stop-and-go modes. The standardized, modular system meets all worldwide safety standards in the automotive industry.

Alongside VAC, we also offer rotary hangers for our overhead conveyors to improve ergonomics even further. They swivel the vehicle, providing a far more comfortable working position for underbody tasks.

Twin Trolley System (T.T.S.®)

The most silent and clean conveyor system ever designed. The Twin Trolley System® (or T.T.S.®) is a system of modules used for the handling of loads in body-in-white, paint shops and final assembly. The modules (aluminum rails, trolleys, drive modules), may be combined in many different ways. The layout is completely customizable by adding switches, vertical and horizontal bends in the free stretches between one drive unit and the next. The movement comes essentially from pairs of two trolleys, that’s why we call it “twin”.

T.T.S.® is the most sustainable conveyor system in the market. Silent operation, no lubrication, low energy consumption are its main features. T.T.S.® is available in four versions:

- T.T.S.® classic: overhead conveyor for medium payloads (e.g. automotive industry, body-in-white, paint and final assembly shops)

- T.T.S.® light: overhead conveyor for payloads up to 500kg (e.g. automotive industry, light components and bodies)

- T.T.S.® heavy: overhead conveyor for payloads up to 6.500kg (e.g. aircraft industry)

- Inverted T.T.S.®: floor conveyor

Floor conveyors

Skillet platform systems

Skillet platforms with an integrated lifting device permit an optimal working level in terms of accessibility and ergonomics for every work section. Work can be carried out on bodies while the workers are continuously transported together with the work platform at low speed.

This is the prerequisite for a precisely coordinated production flow, which is indispensable in modern just-in-sequence production. Here, too, we supply individual solutions, e.g. platforms with up to five lifting tables or particularly low designs.

operation without a pit and a stroke of up to 1.45 m. In addition, there are no specific requirements that the building must meet and the system is easily accessible.

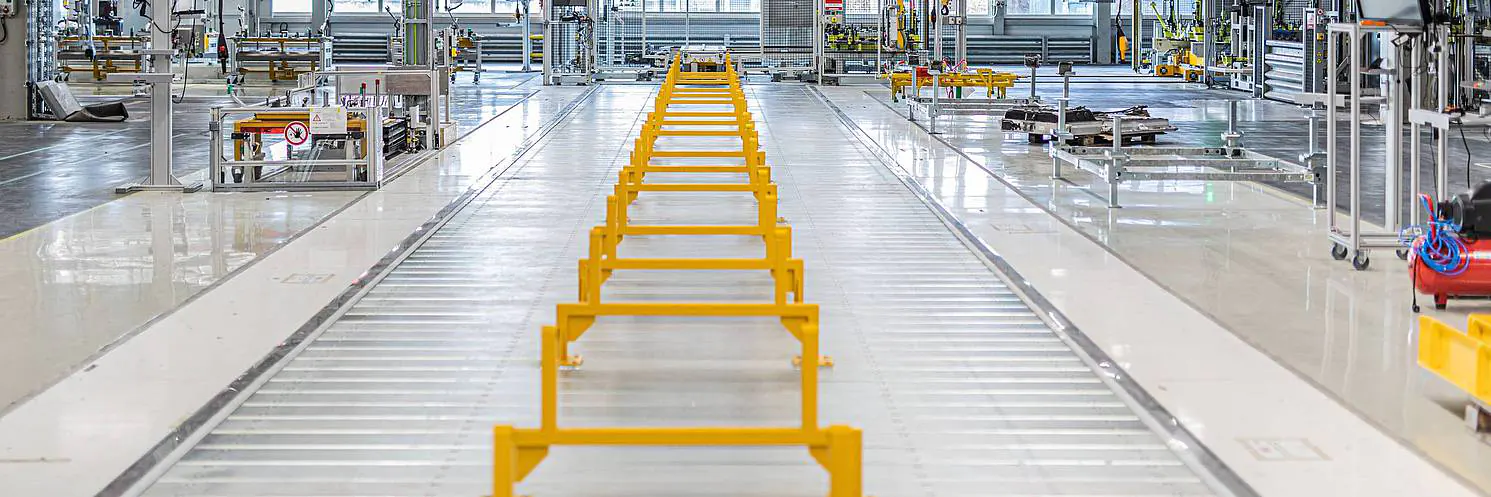

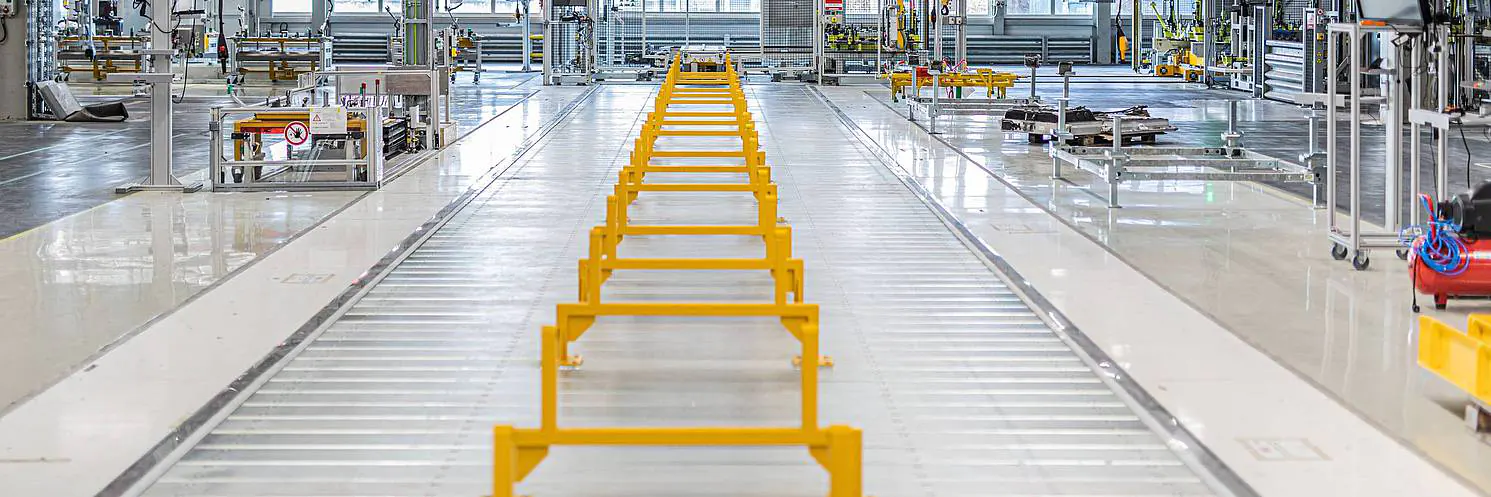

Roller bed systems

The bodies are transported on roller beds for connections from the paint shop and from the decoupling buffer. The elements are identical to those in the paint shop area. Roller bed systems are suitable for skid transport, pre-assembly and marriage in final assembly.

Slat conveyor systems

We offer a wide range of slat conveyors. Their modular design makes them suitable for a wide variety of applications. They are used to transport not only workers but also bodies with wheels. Upon customer request, we supply one- or two-strand plastic or steel slat versions. Special versions in stainless steel, e.g. for the water test, are also available. Slat conveyors are characterized by robust chain drives and a high resistance to moisture, dirt and high temperatures.

Plastic link bands

This technology is used as a man-rider conveyor or to transport car bodies. The benefit of plastic link bands is that they are low-maintenance, and on account of being contamination-resistant, ideally suited for use in wet areas.