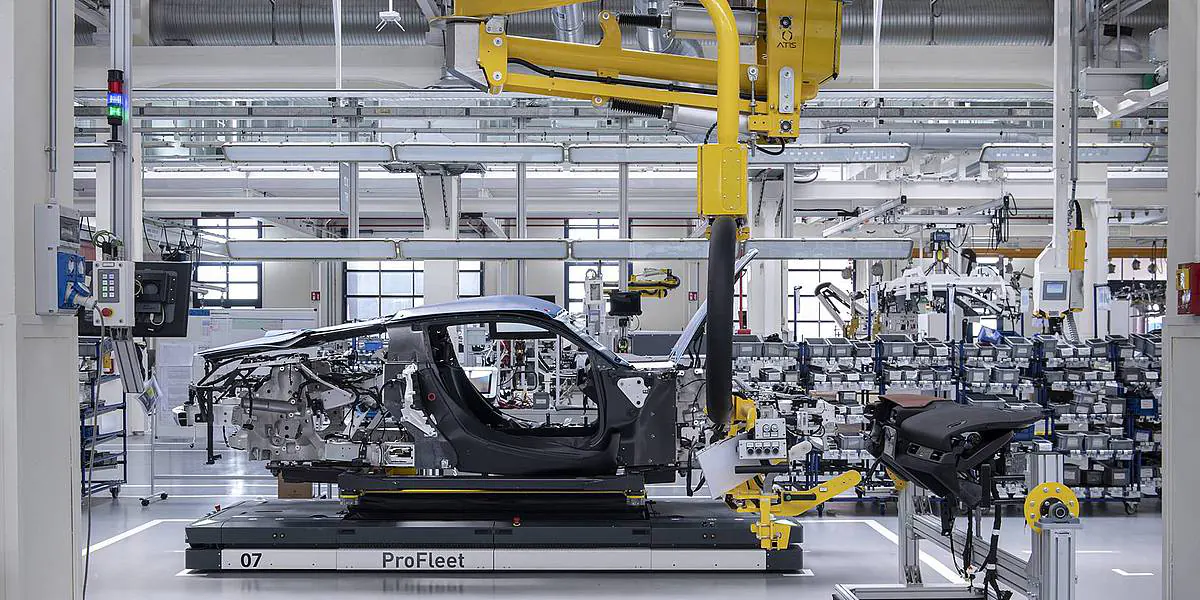

ProFleet

A range of automated guided vehicles (AGVs)

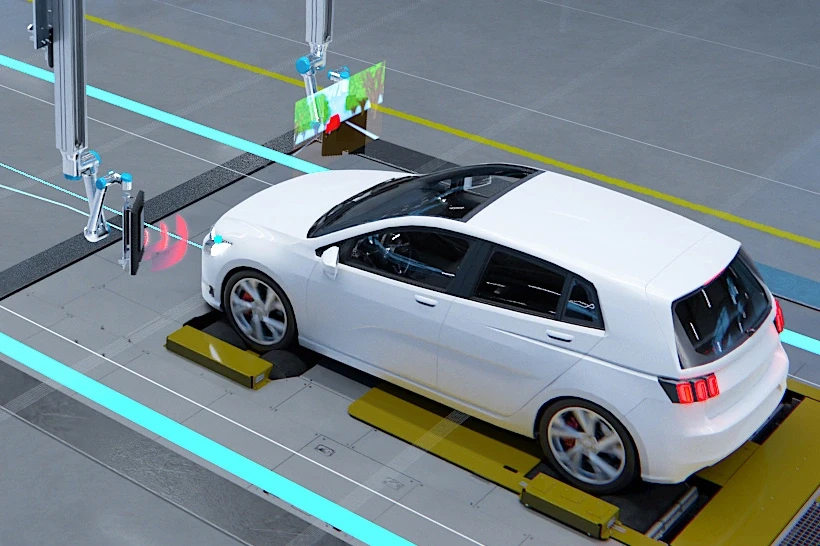

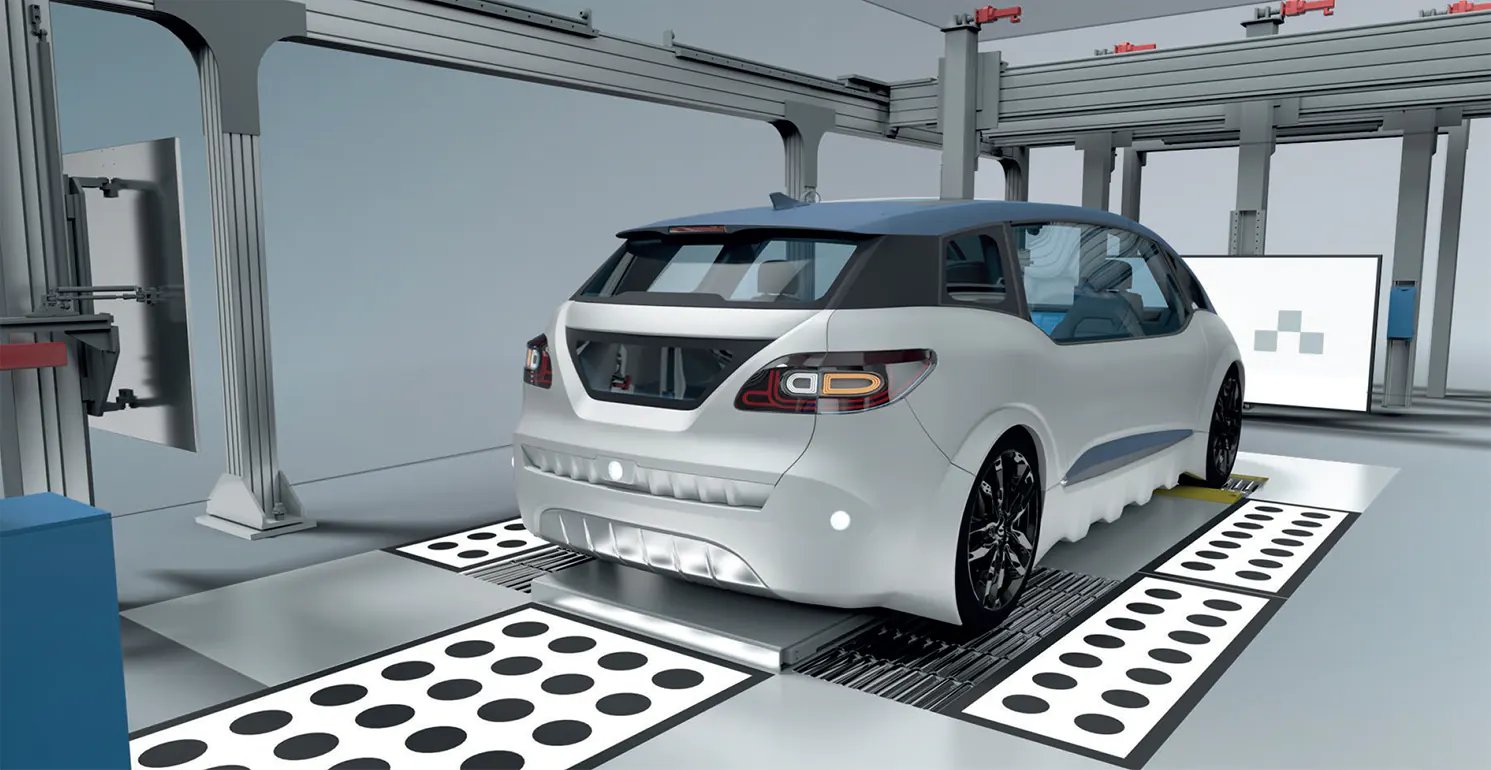

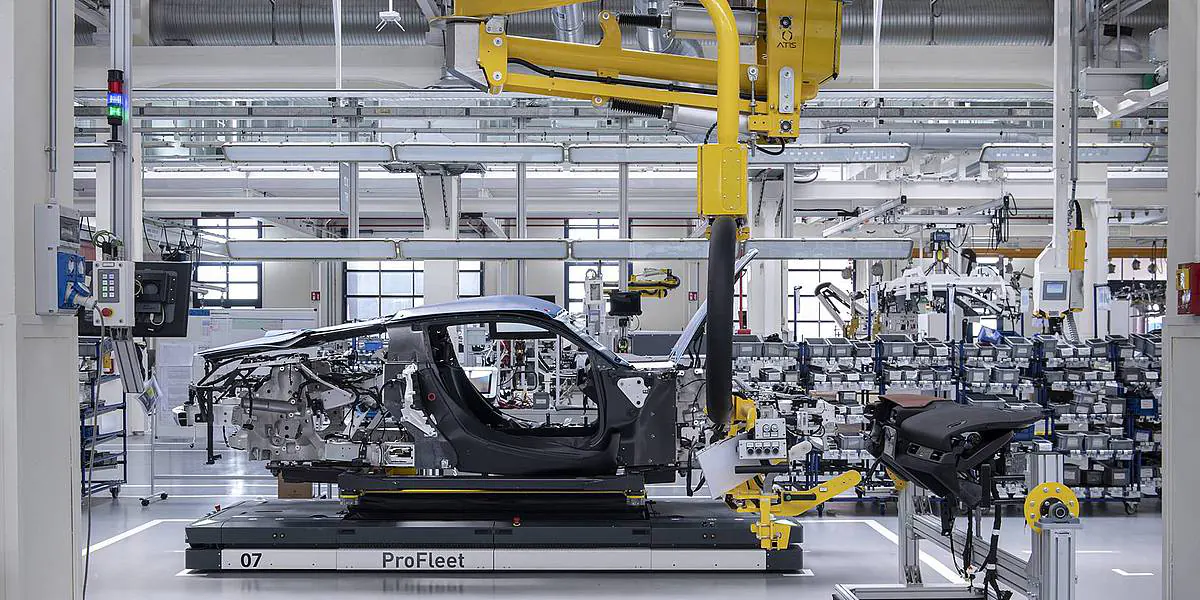

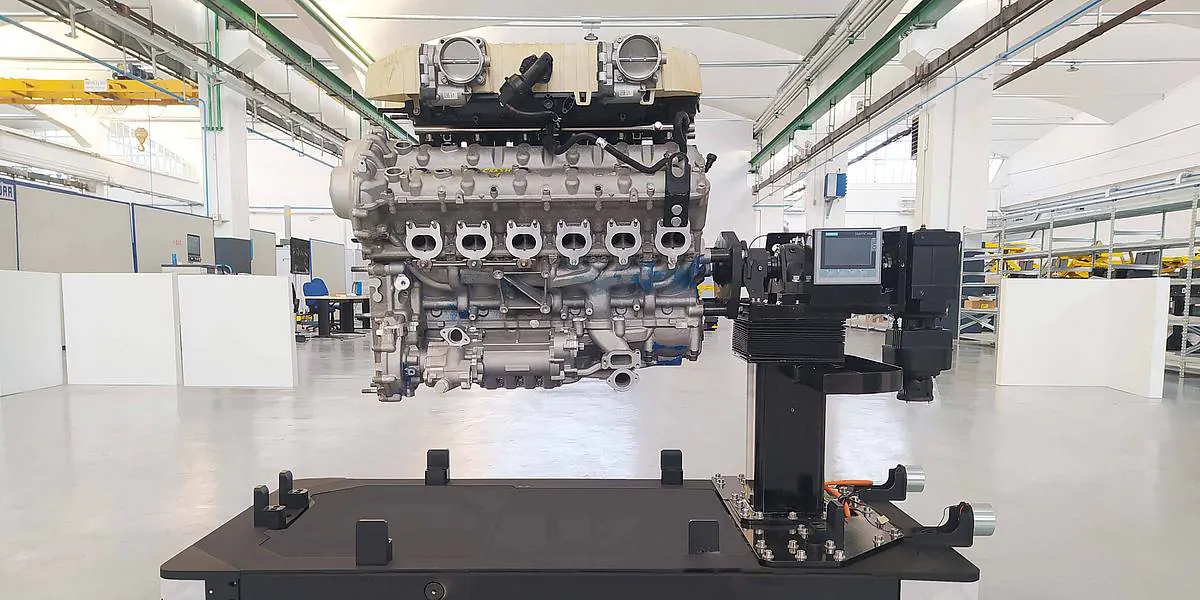

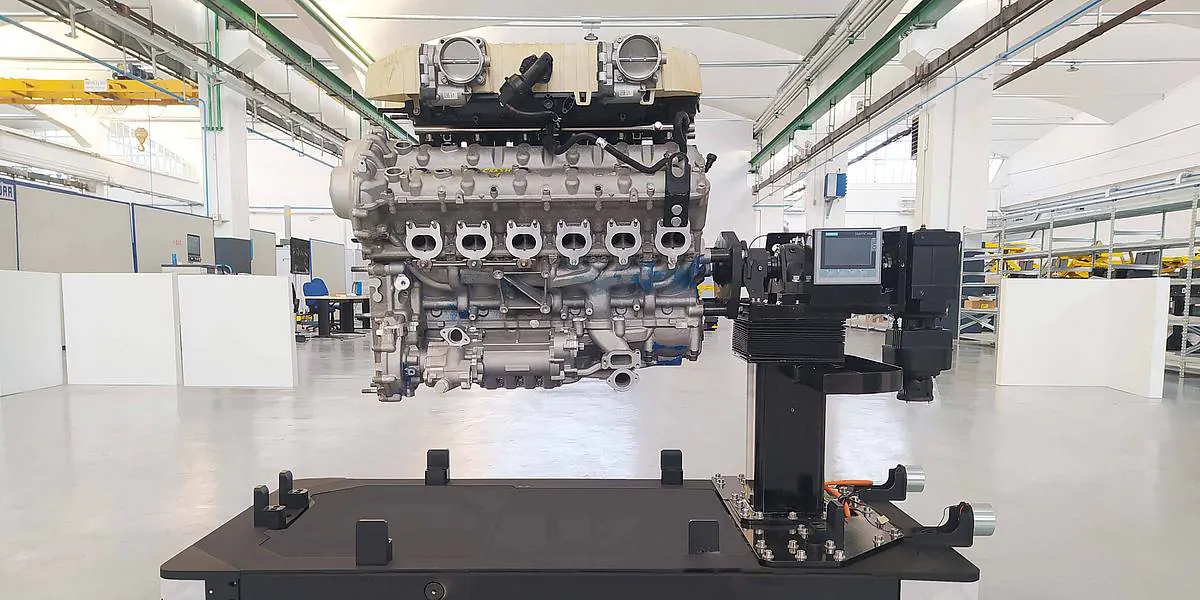

AGV is the perfect solution for many activities within the automotive and non-automotive industry. It is ideal as a working station and for the transport and transfer of parts along a production line. For example, in a final assembly shop the AGV moves along different stations to get the mechanical parts of the car loaded on a tooling plate firmly locked on it. The AGV can interact with other systems, in particular with external transfer devices for loading and unloading of the tooling plate. All our solution can be customized according to specific needs. All our AGV fleets can come with the CPM App for smartphone and tablets.

The benefits of ProFleet:

ProFleet is safe:

Originally designed by Dürr’s Italian subsidiary CPM for assembly shops in the automotive industry, where the density of workers is higher than in other production environments and where man-machine coexist, ProFleet guarantees the highest level of safety. ProFleet is TÜV certified according to Level D Performance. Its compliance to the strictest safety regulations makes it probably the safest technology of its kind in the market, allowing people being around.

ProFleet is cooperative:

Its design guarantees the highest ergonomics standards and the best accessibility while enabling assembly operations.

ProFleet is reliable:

ProFleet guarantees a maximum in efficiency and reliability in compliance with extremely high technical standards required by today’s OEMs and start-ups.

ProFleet has an open software architecture:

Fleet management, AGV navigation, safety systems are all managed by Siemens PLCs.

- Customers can modify and customize software on their own with resources already available in the plant

- If needed, CPM gives direct assistance, without depending on other suppliers

- The system is VDA5050 compliant

ProFleet is Industry 4.0 compliant:

It can be provided with its dedicated app, that allows

- Remote control and monitoring

- Clustered push notifications

- Diagnostic logs

- Preventive and predictive maintenance

And the app is fully customizable. Along a production path, ProFleet interacts with other systems and equipment (e.g. overhead conveyors) and accurately synchronizes with them. In this way, a wide range of technical solutions and layouts can be realized.

ProFleet is flexible:

It combines the most innovative concepts of smart, modular, scalable and easily modifiable production. And if a customer wants it designed to a specific model, minor changes at minimal cost make it suitable at a later date for integration into the production flow of new models, whatever their size or weight.

ProFleet allows opportunity charging:

ProFleet can be charged in-line or at any point of the plant while operating, without any impact on production or cycle time.

ProFleet is maintenance friendly:

It was intended for easy maintenance and quick replacement of components.

- Electrical components easily accessible from its sides

- No need for cycle calibrations

- Motors fixed to achieve the longest cable life

- Operations from the underside not required

- Very easy to move even without energy on board