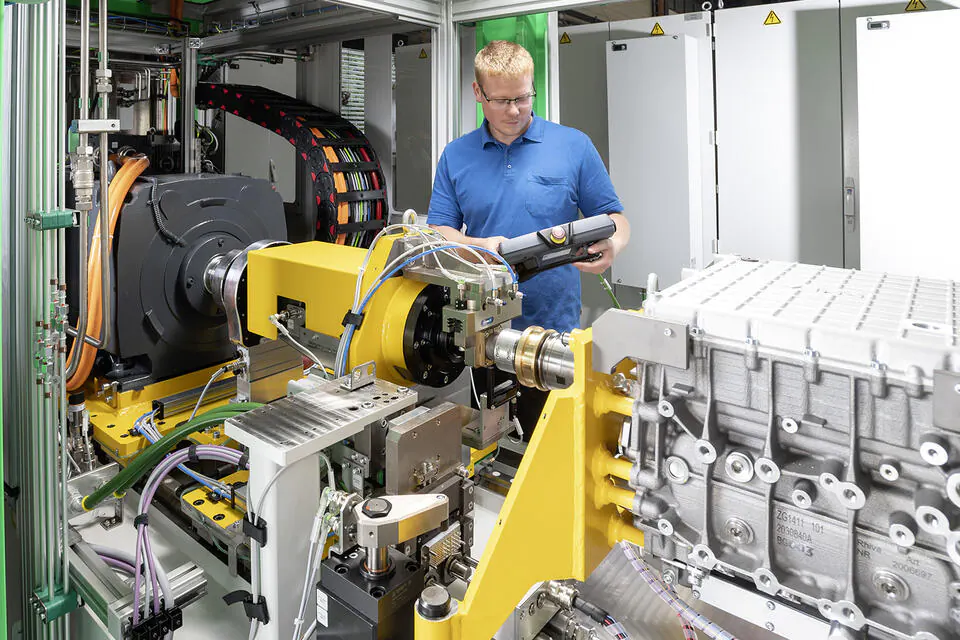

e-Drive Testing

TRUST teamtechnik, THE MARKET LEADER

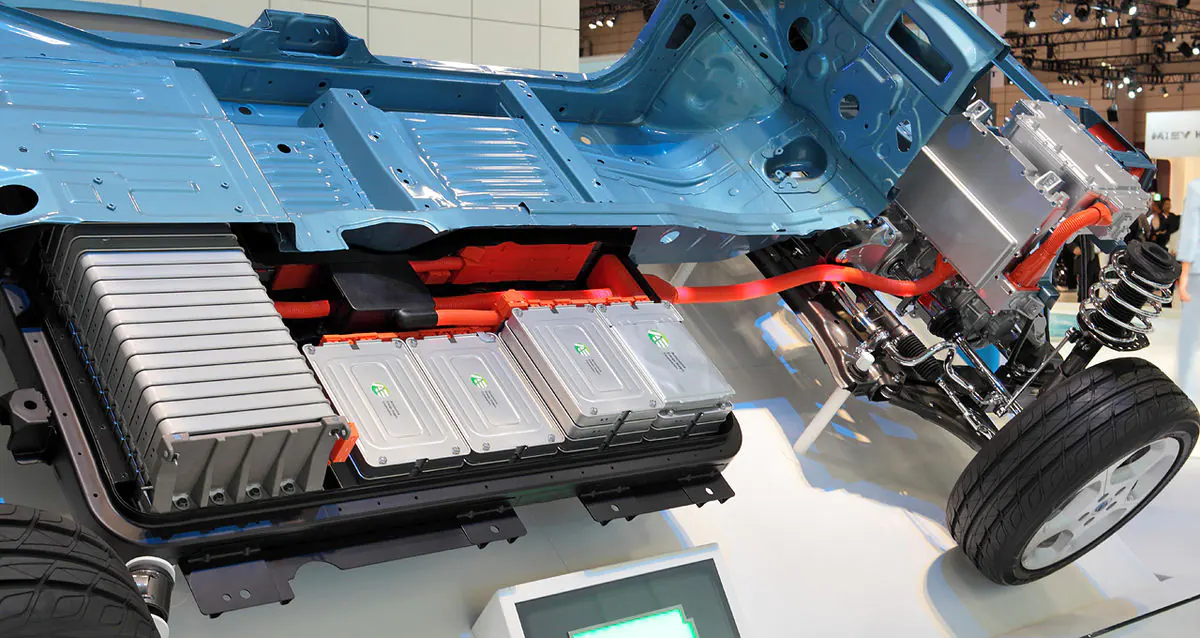

From 6-gear manual transmissions through to automatics and dual clutch transmissions, from hybrids through to full electrics – the teamtechnik test benches have already taken a few quantum leaps in drive technology. After all, the company has spent the last 25 years building systems which are used to put drive units through the most rigorous testing.

Modular EOL test concepts for the latest e-drive systems. Fully automated with flexible test software developed in-house. Full test functionality – from electrical testing to dynamic NVH testing.

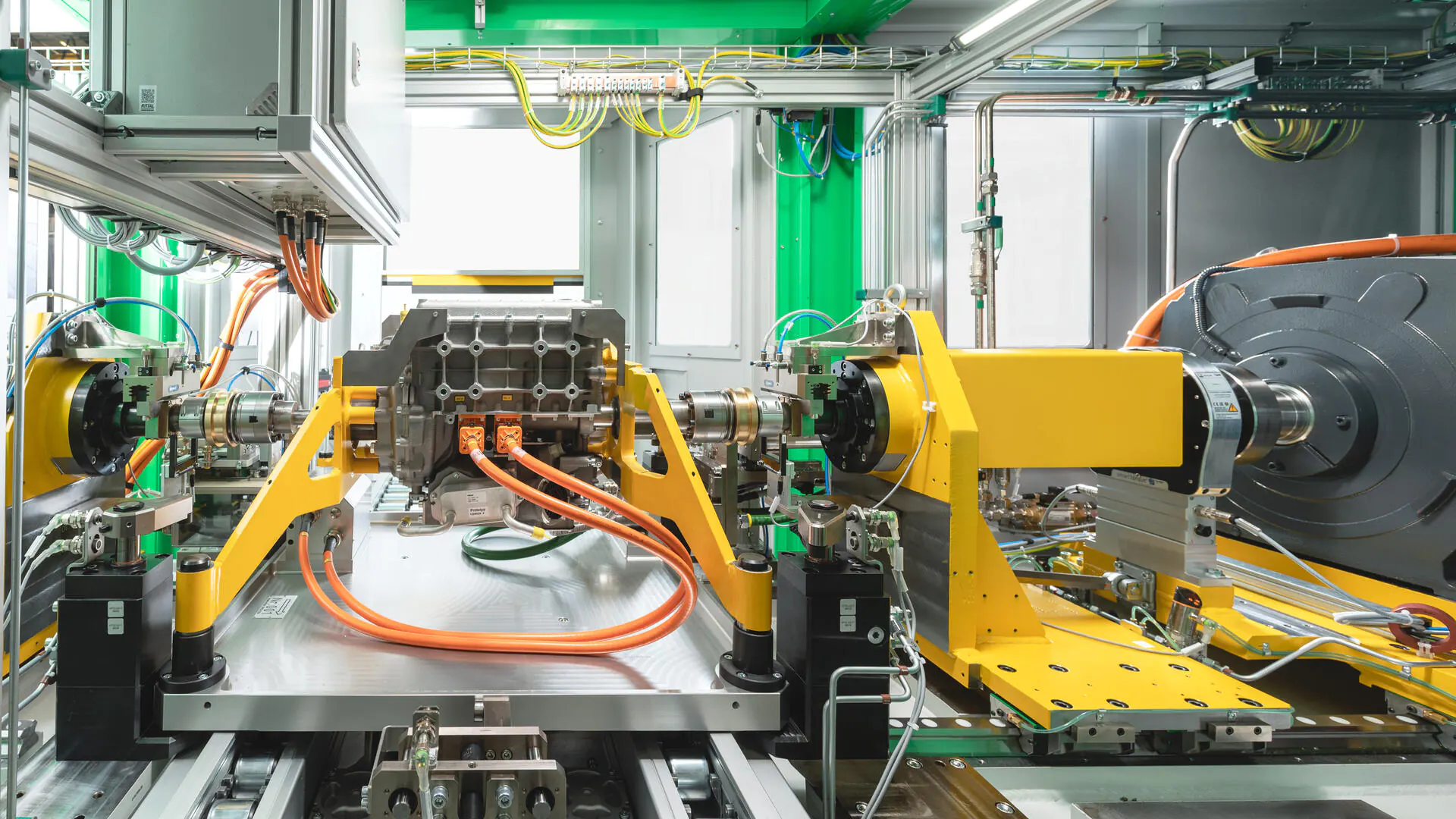

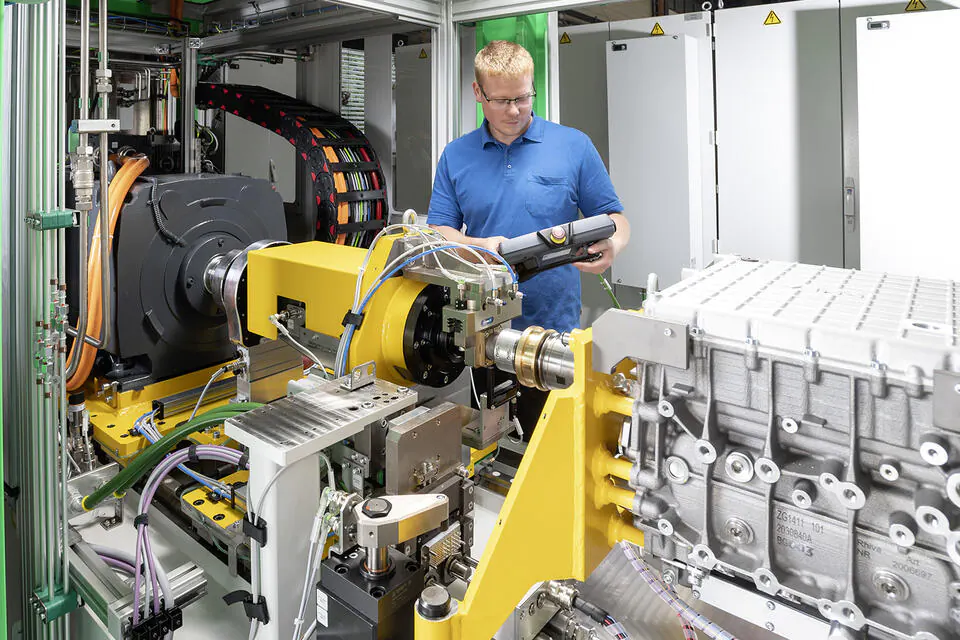

Maximum Flexibility and Quality for Testing Systems

- High drive system dynamics

- Excellent control quality for maximum reproducibility of measurement results

- Closed energy circulation within test bench

- Control of high currents and voltages

- Electrical tests and calibration

- Function and noise level testing

- Battery simulation

- Control unit communication and full data tracing

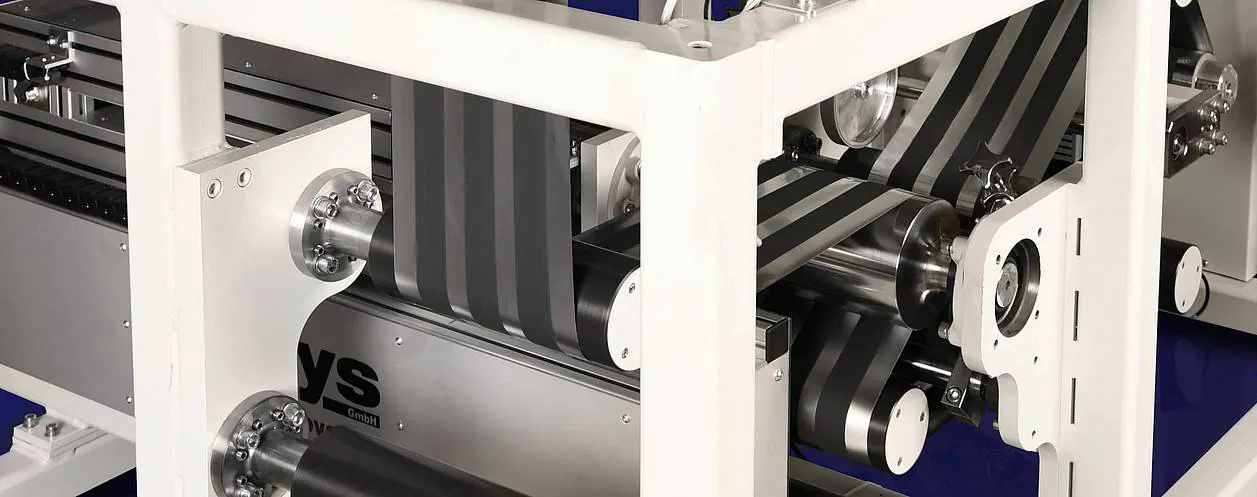

e-DRIVE TEST – the trusted basis

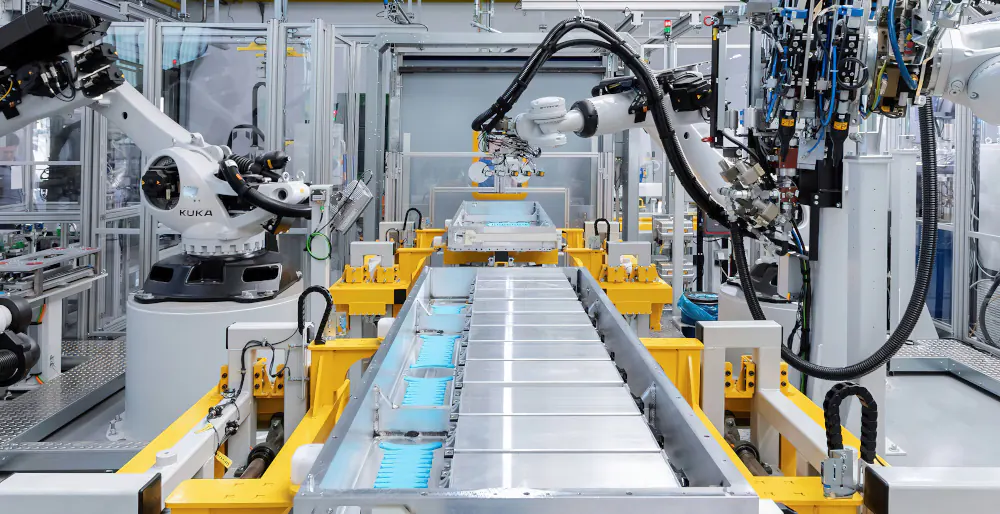

Our standardized e-DRIVE TEST testing platform enables us to test a wide variety of product types and variants using the same modules. On this basis we create testing systems, from individual test benches through to fully-automated test fields with additional stations such as assembly, oil filling, flashing and set-up.

Proven Testing Technologies

- Noise, Vibration, Harshness (NVH)

- Performance and efficiency test

- Park lock and differential test

- Oil filling and flushing

- Cooling water flushing

- Media supply (oil, water)

- Back EMF, cogging, ripple

- Resistance, insulation

- Resolver test

- Communication (CAN, FlexRay, LIN)

- Fully restbus simulation

teamsoft – the innovative test software from teamtechnik

For e-drive test benches teamsoft.TEST is an innovative software:

- NI® LabVIEW®-based runtime system

- Real-time data acquisition

- All data is stored in a Microsoft® SQL Database

- Customizable reports

- Customers can Configure test sequences

- Continuous versioning

- Data analysis

- Intuitive graphical programming

- Flexible operator HMI design