Automation Technology in Medical Industry

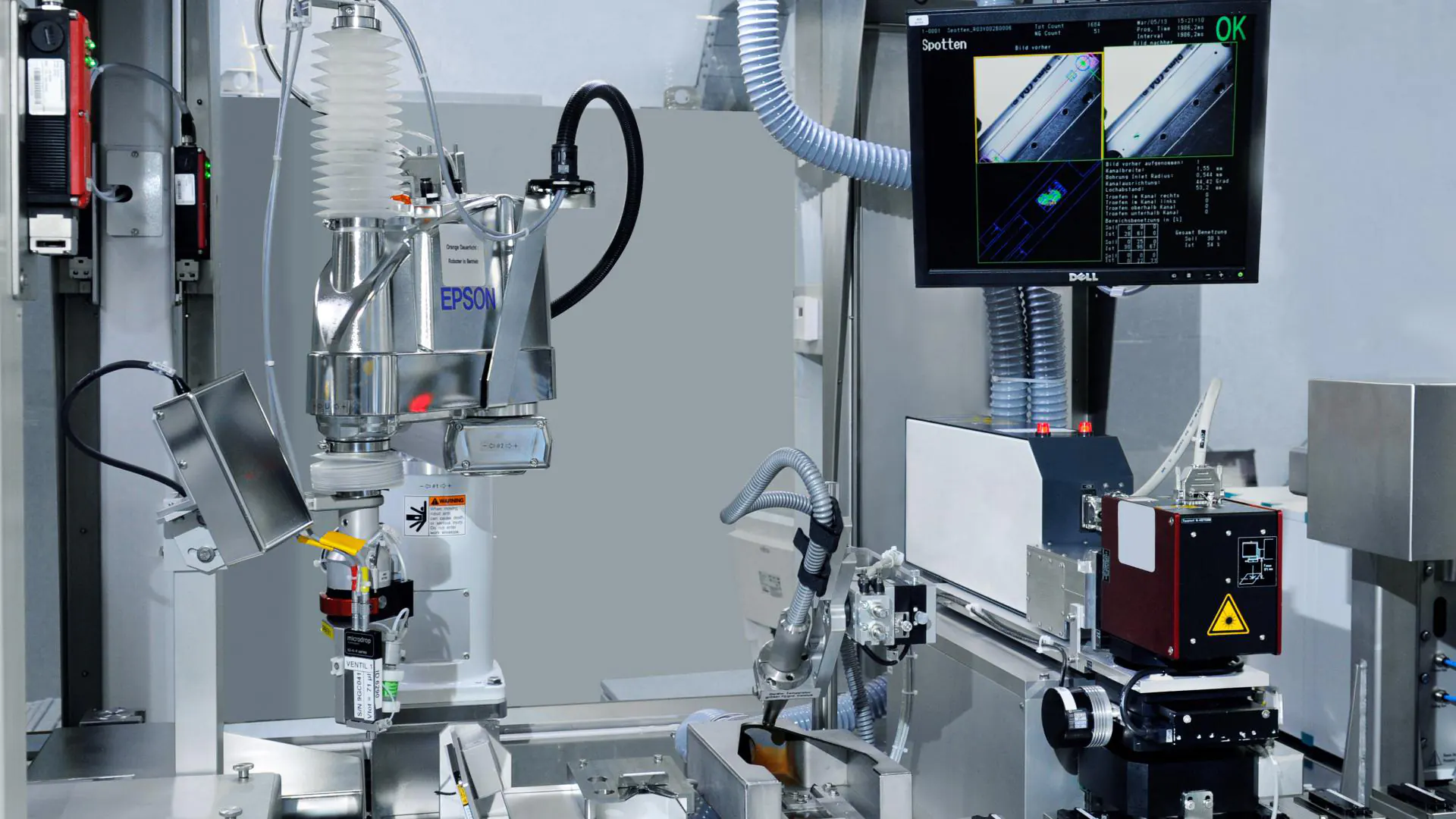

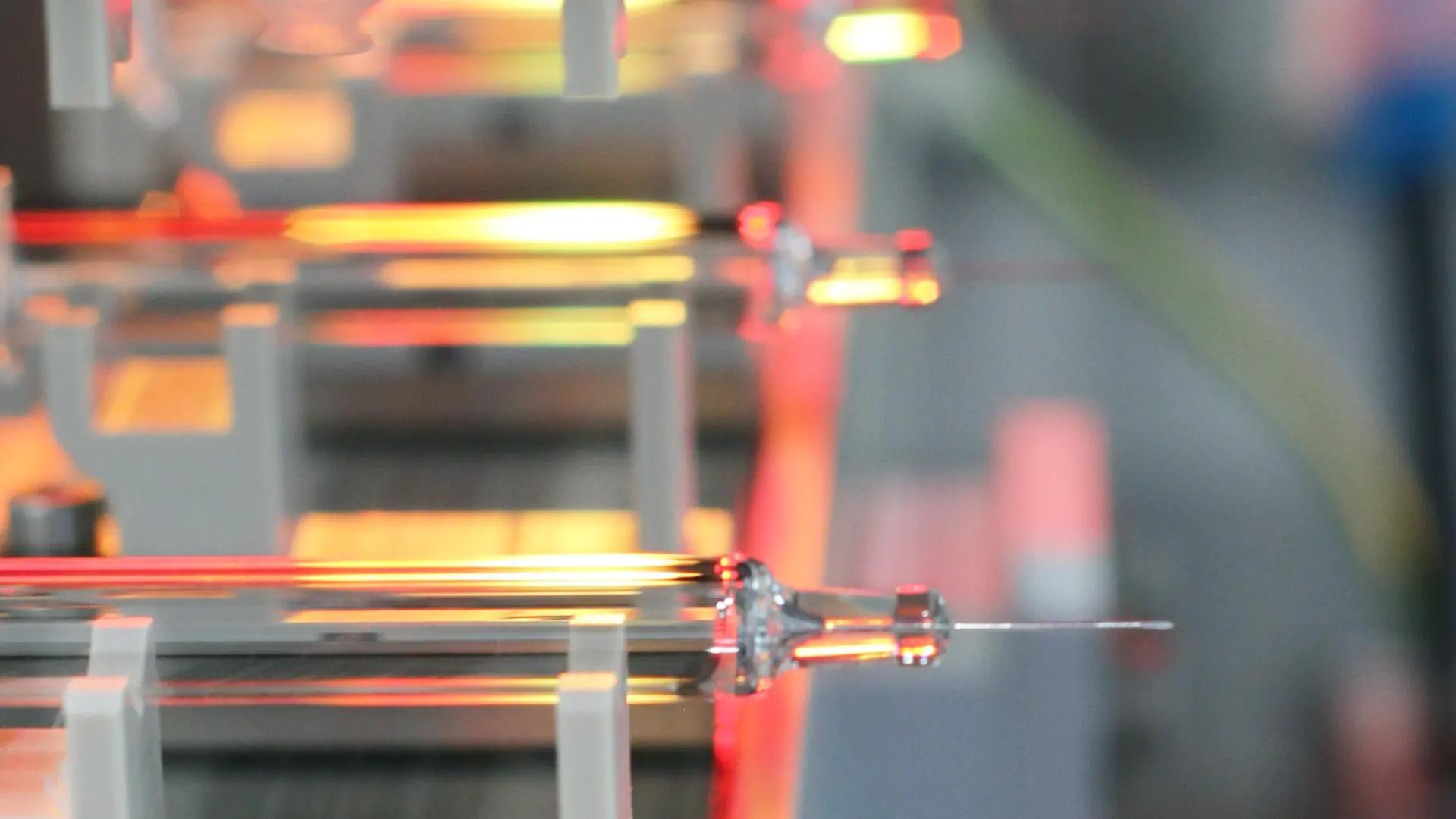

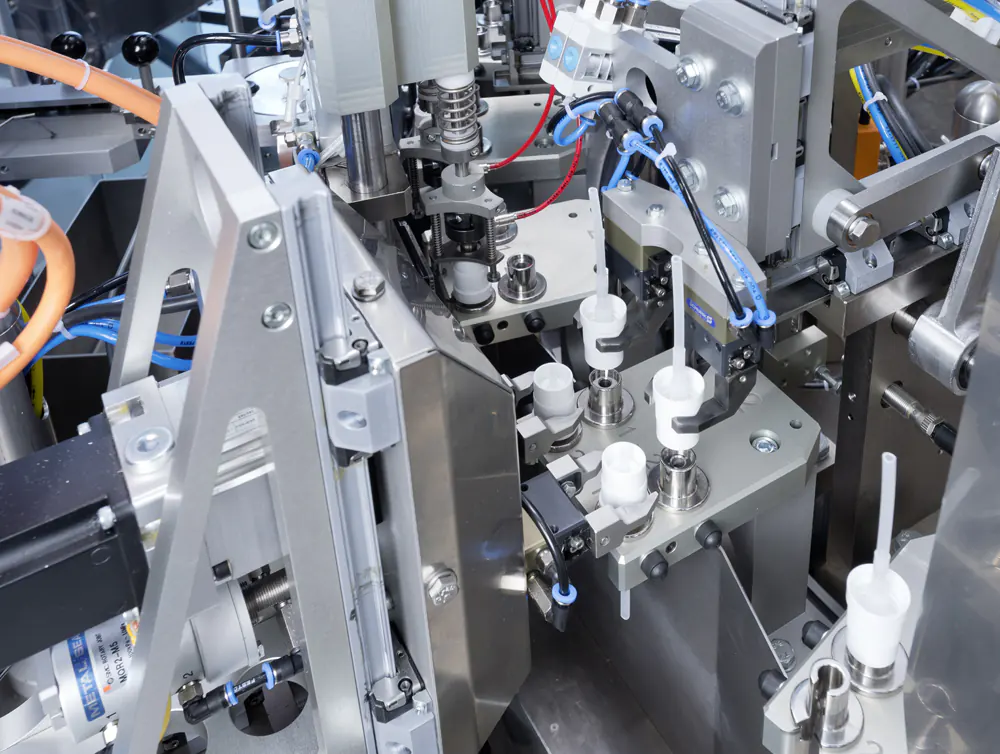

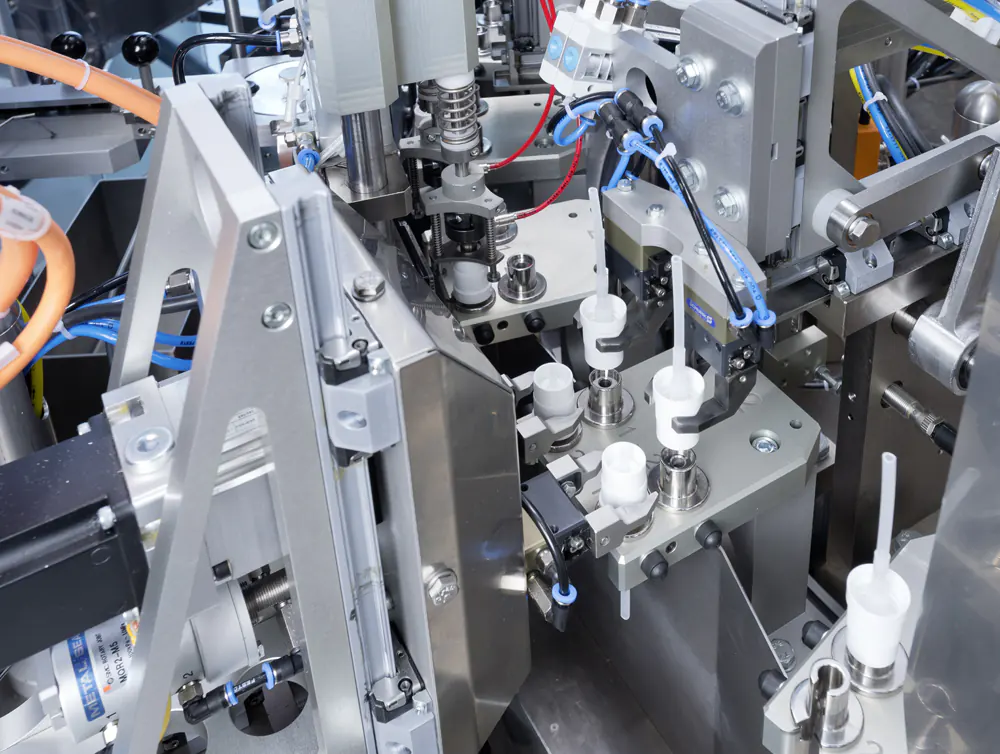

Systems for production, assembly and testing of medical technology products are Teamtechnik’s second largest product area. The company covers the entire spectrum of customer demands: from the entry-level machine for test purposes to the high-performance large-scale production system in which parallel production takes place on up to eight production tracks. The systems are packed with high-tech components, such as feeding, dosing and testing technology, handling systems, sensors and grippers that precisely position even the finest needles for injection systems. Added to this are optional laser welding stations, gluing technology, palletizing and packaging equipment or vision systems with up to 15 cameras, as well as complete software packages.

Inhalers, injectors, blood collection tubes, pipette tips and infusion sets, for example, are manufactured in quantities of several million per year on systems from Hekuma and Teamtechnik. The world market for such disposable medical products is growing by around 8% per year. The main reasons for this are the growth in the world’s population, rising life expectancy and the increasing quality of medical care.

The portfolio is completed with EcoClean solutions for fine cleaning processes with aqueous multi-stage ultrasonic cleaning lines, which is mainly used in medical and optical industry. Increasing cleanliness requirements and consistent cleaning results are common demands for medical implants and devices. UCM, a member of the Ecoclean Group, stands for Ultrasonic Cleaning Machines and offers optimized solutions ranging from in-process to final cleaning prior to packing.