Parts cleaning in the medical industry

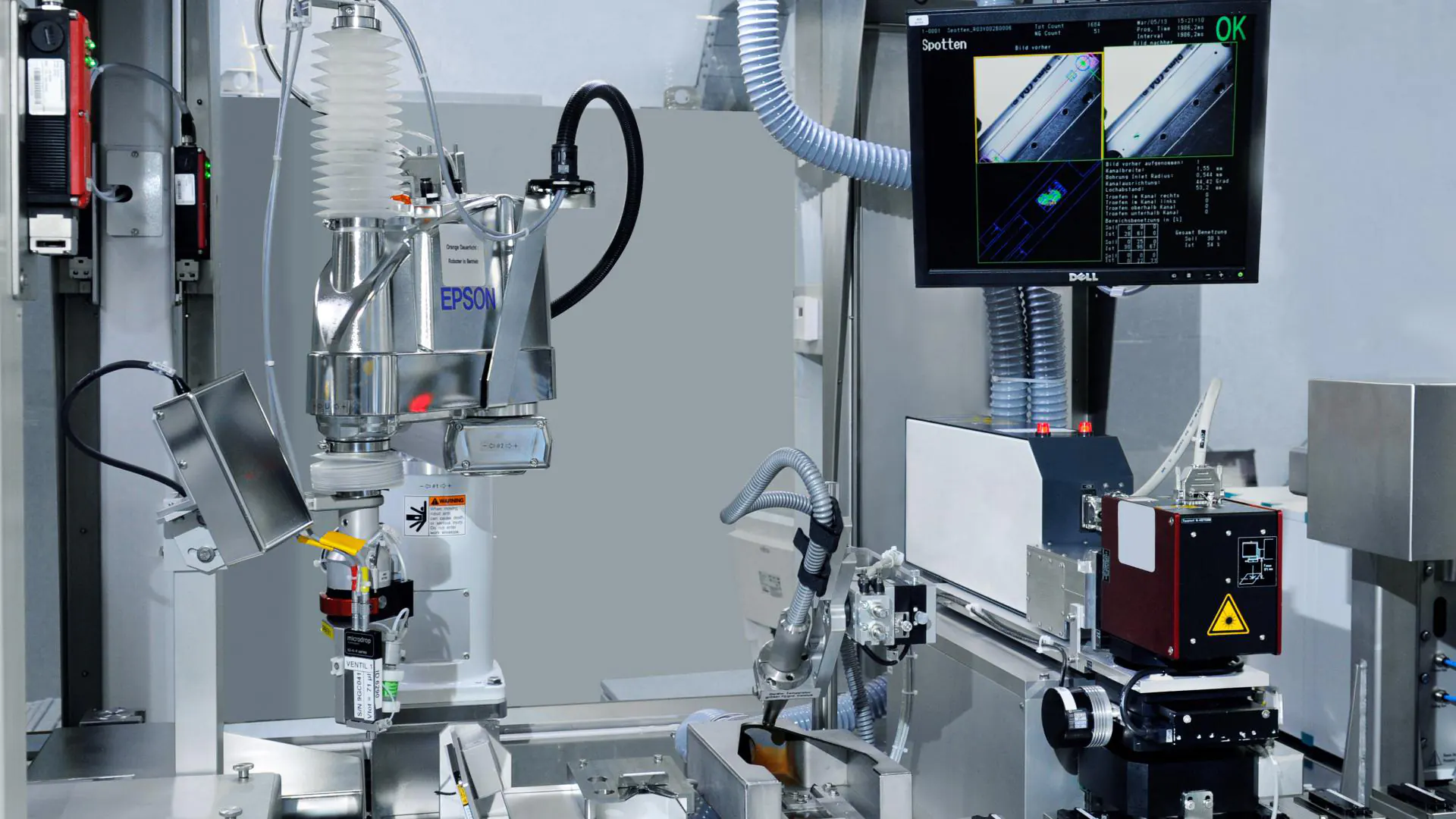

Medical products such as implants, instruments, cannulas and endoscopes, place specific demands on cleaning processes and packaging. These include the reliable removal of contamination from manufacturing processes, even from capillaries, complex geometries and porous surfaces. All traces of powder must be removed from additively manufactured components using powder bed processes. Parts and assemblies for large-scale equipment such as X-ray systems or computer tomography and magnetic resonance imaging (CT and MRI) system also require extremely high levels of particulate and thin-film cleanliness. In addition, regulations such as FDA and MDR must be complied with in terms of product identification, equipment qualification, documentation and traceability of components and processes. For these tasks in the medical device industry, Ecoclean offers future-oriented, turnkey cleaning solutions including cleanroom and packaging systems that are available around the globe, with local service.

Cleaning technologies for the medical industry

As a full-range supplier, Ecoclean covers the entire spectrum of parts cleaning. In addition, the company’s portfolio includes solutions for aqueous and solvent-based surface treatment, automation, cleanroom systems, as well as packaging systems for implants and instruments with validated packaging materials. Adapted to the specific demands and applications (e.g. pre-, intermediate or final cleaning, material, component geometry, type of contamination and cleanliness requirements), different systems are available for individual part and batch cleaning with environmentally compatible solvents and water-based media. Partial cleaning can be carried out reliably and efficiently with our dry cleaning processes. Targeted surface activation, for example of specific areas of implants to optimize osseointegration, is made possible by our water-based solutions for activating surfaces without the addition of abrasive media. Software, RFID technology, audit trail and CFR 21 specially developed for the medical technologies sector ensure the end-to-end identification, documentation and traceability of components.

Components:

- Implants, e.g. hip joints, knee joints, spinal implants

- Instruments, e.g. surgical instruments, scissors, saws, clips, forceps, scalpels, retainers, nails, screws, drills

- Dental parts, e.g. implants

- Endoscope components

- Syringes, cannulas

- Inhalers

- Components for large devices, e.g. MRI, CT, X-ray systems

- Additively manufactured components, e.g. implants, prostheses

Applications:

- Pre-cleaning, e.g. after machining processes

- Deburring and cleaning

- Intermediate cleaning between production processes, e.g. after grinding and polishing

- Final cleaning with passivation, e.g. prior to packaging and sterilization

- Assembly-integrated cleaning

- Surface treatment, e.g. roughening to improve osseointegration

- Surface activation, e.g. roughening before coating, bonding