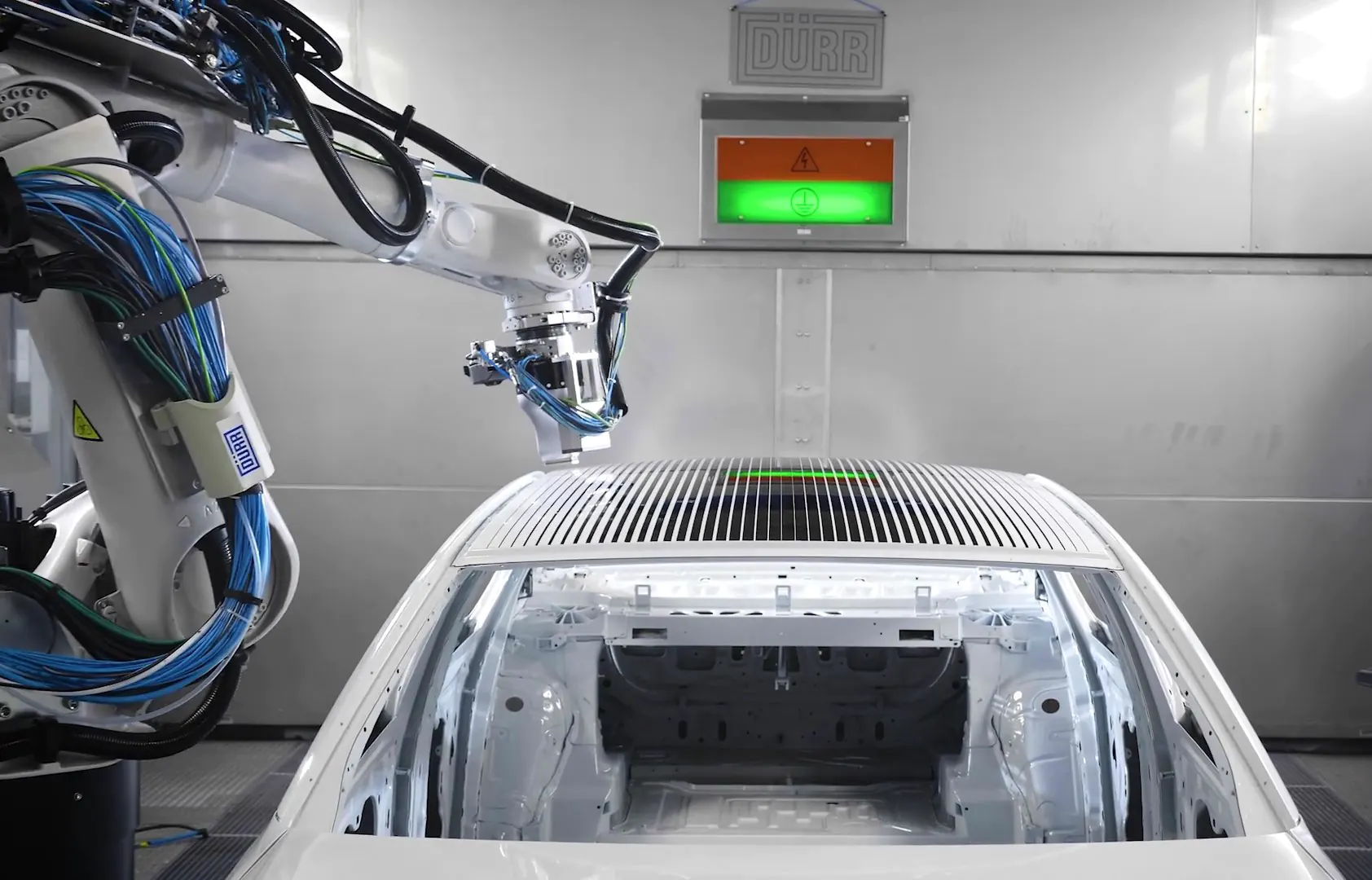

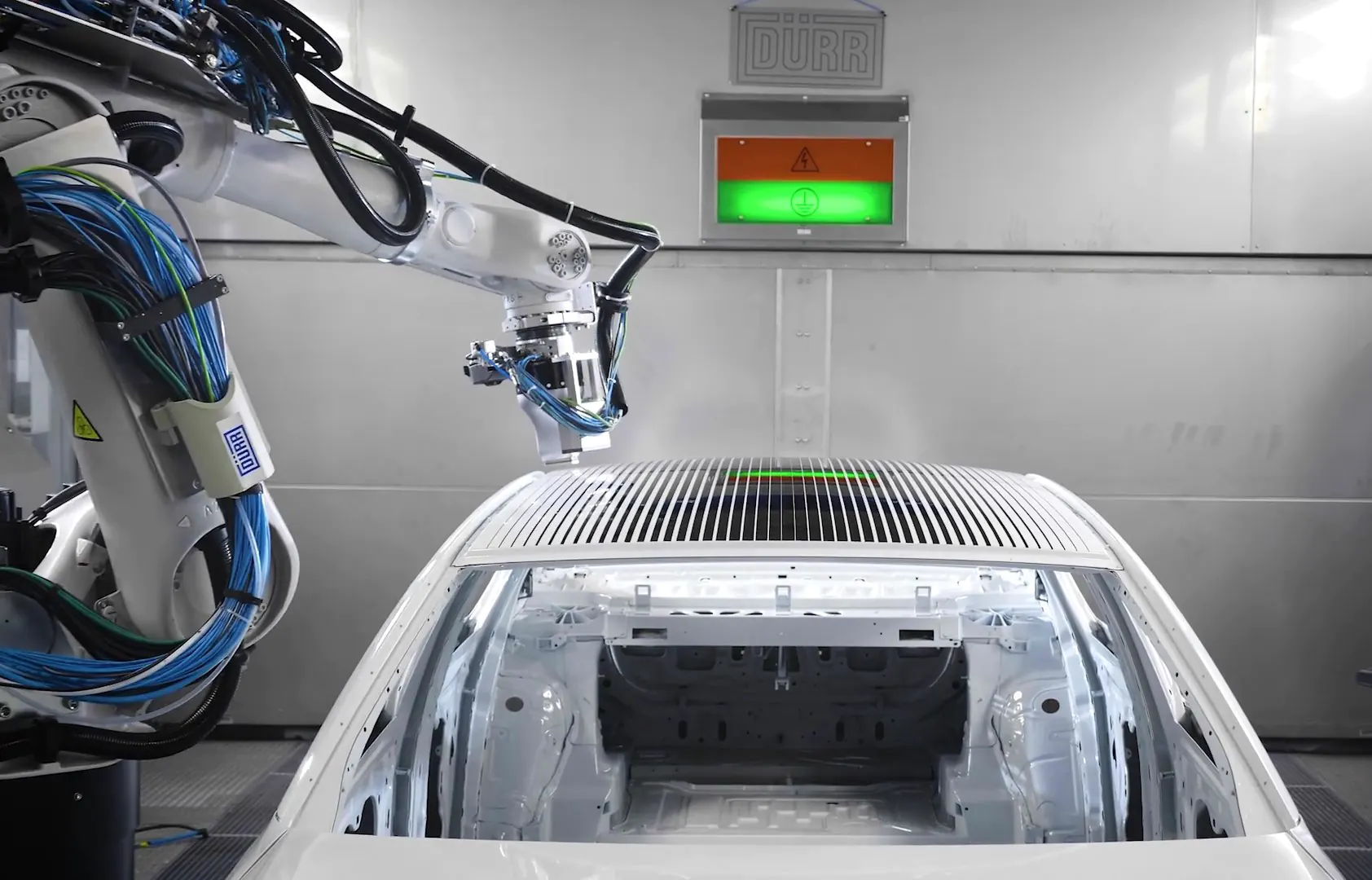

EcoPaintJet/EcoPaintJet Pro – Overspray-free paint application

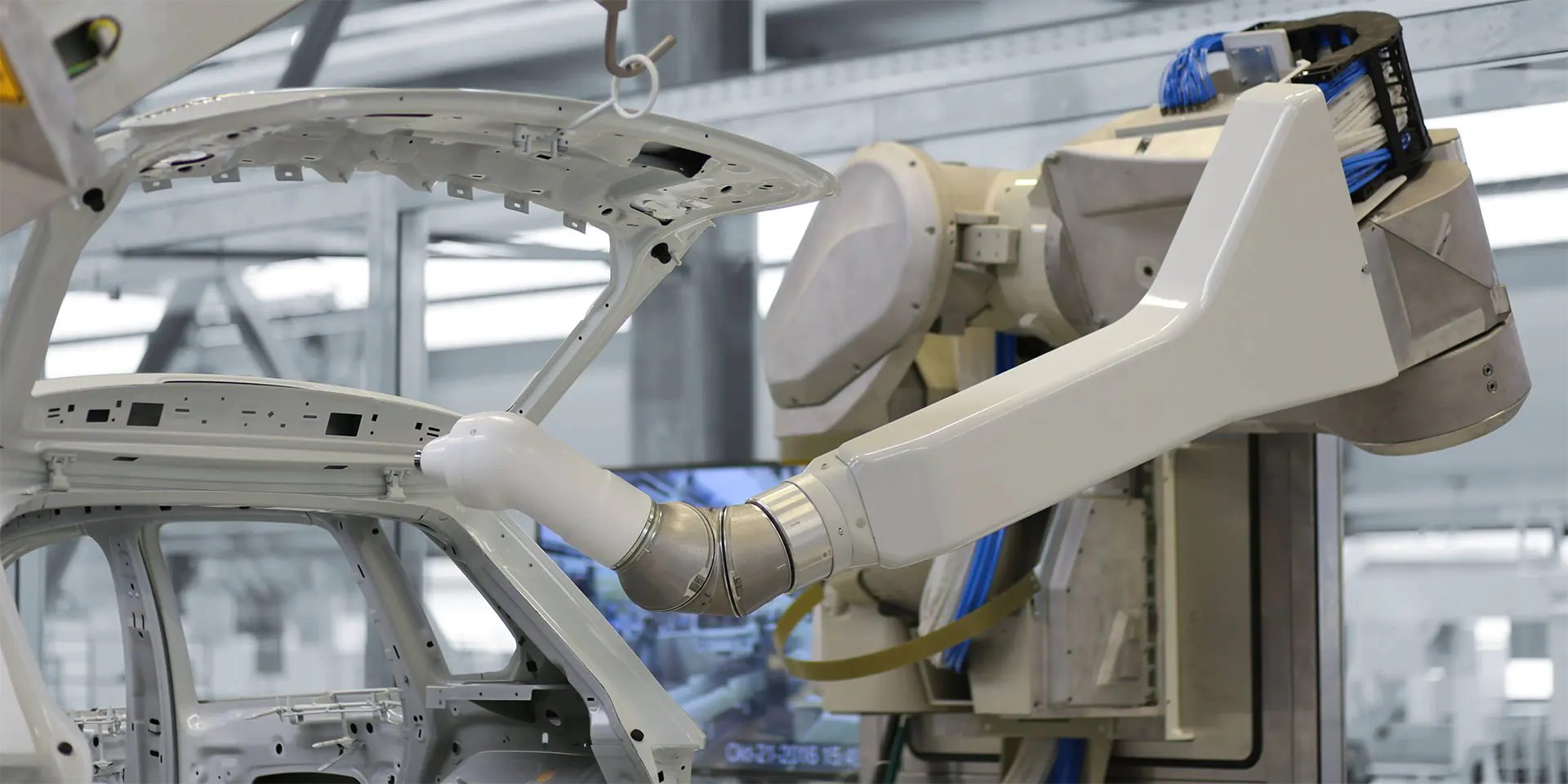

The EcoPaintJet’s perfectly coordinated combination of robot, measuring system and applicator ensures highly defined coating. The measuring system uses sensors to measure the chosen surface and sends the data to the control software. The software then constantly calculates exactly how the applicator should travel over the surface and how much paint has to be dispensed. The crucial thing about the applicator is that it does not produce overspray. During two-tone painting, this new innovation removes the need for manual and time-consuming masking. This new process saves time and is environmentally friendly.

Operating principle

The EcoPaintJet can be integrated into the painting line of new plants or can be fitted to existing plants as an additional module. For two-tone painting in the automotive industry, the EcoPaintJet is installed onto a robot and applies the decorative paint directly onto the chosen surface. The underside of the applicator is equipped with a nozzle plate that has around 50 almost invisible holes, each approx. one tenth of a millimeter in diameter. The paint is applied through these holes in parallel lines from a distance of 30 mm. This makes it possible for the EcoPaintJet to apply paint very precisely and with absolutely no overspray.

The benefits of EcoPaintJet:

- Highly precise and sharply defined coating

- Body masking no longer necessary

- Time required for two-tone paint application significantly reduced

- Automated manufacture of customer-specific requirements

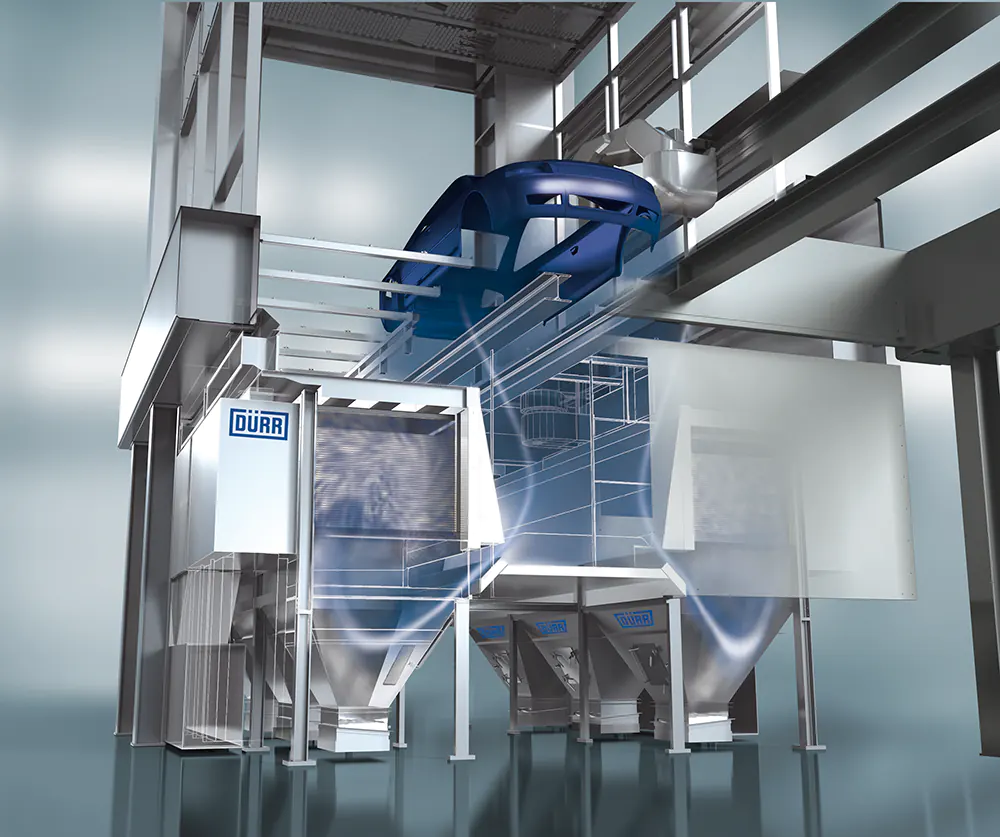

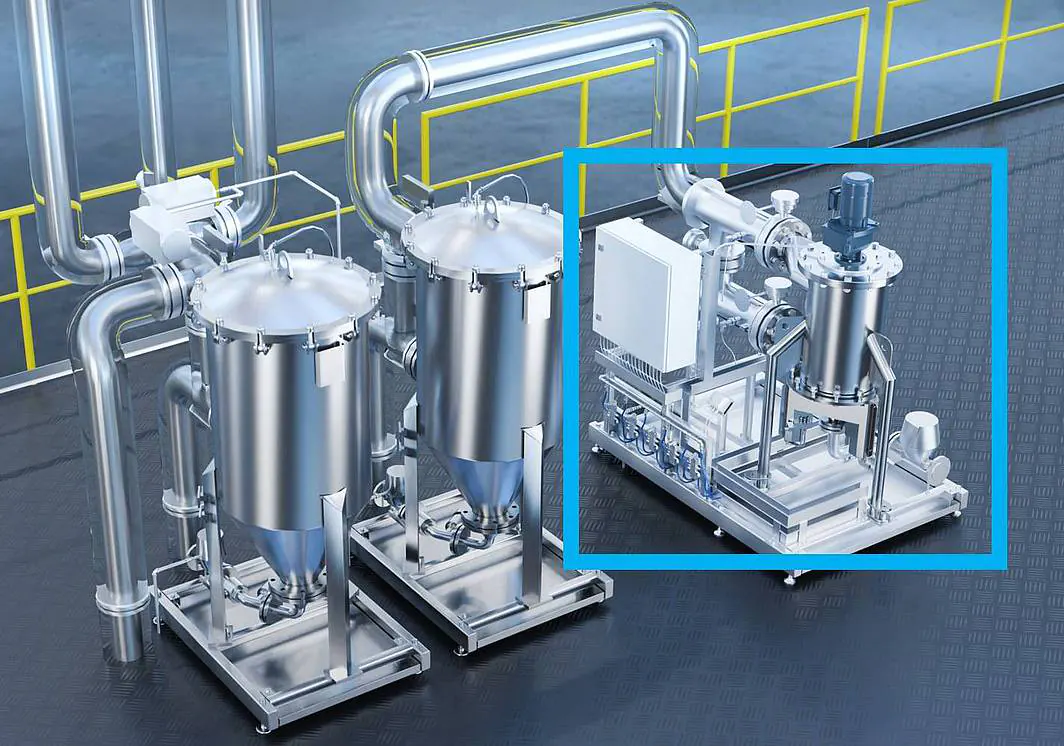

- No Scrubber is required

EcoPaintJet Pro

In the latest version of the EcoPaintJet Pro, every hole in the nozzle plate can be opened and closed individually. This results in even more options for product personalization. This advanced technology allows vertical surfaces, roof arches and door panels to be coated in contrasting colors and, in particular, enables patterns to be applied where otherwise a wrap would have to be used.