Our consulting and planning process is designed to define your current situation, identify how your operation links together and leverage those interfaces. By harmonizing workflows, we’re often able make significant improvements in manufacturing processes and throughput times. We find that smart tools and utilities and lean layouts are key prerequisites in reducing unit costs effectively.

We take a result-oriented and systematic approach to project management. So, when planning logistics and process sequences and implementing the resulting measures and targets, we ensure everything happens on time and nothing compromises your operations.

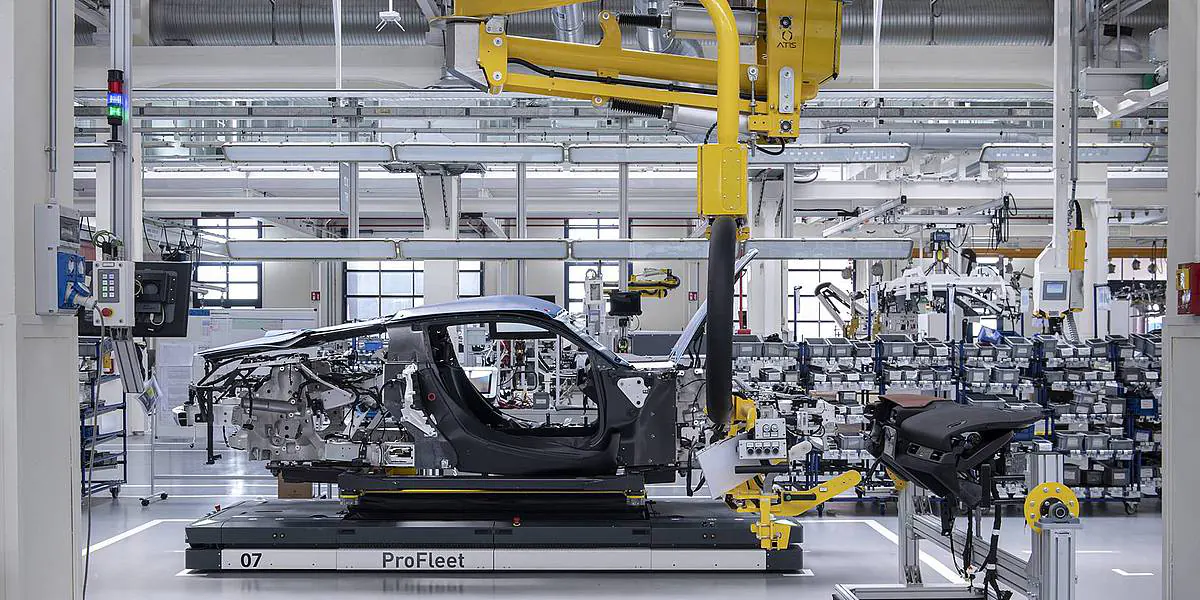

During the ramp up, the track & tracing shop floor management monitors the implementation so that you can quickly and flexibly leave obstacles behind. After a successful SOP we are handing over the controls back to our customers, because our primary goal has been achieved: The customers production is up and running, Although, the production optimization continues.